» Responsible procurement of raw materials

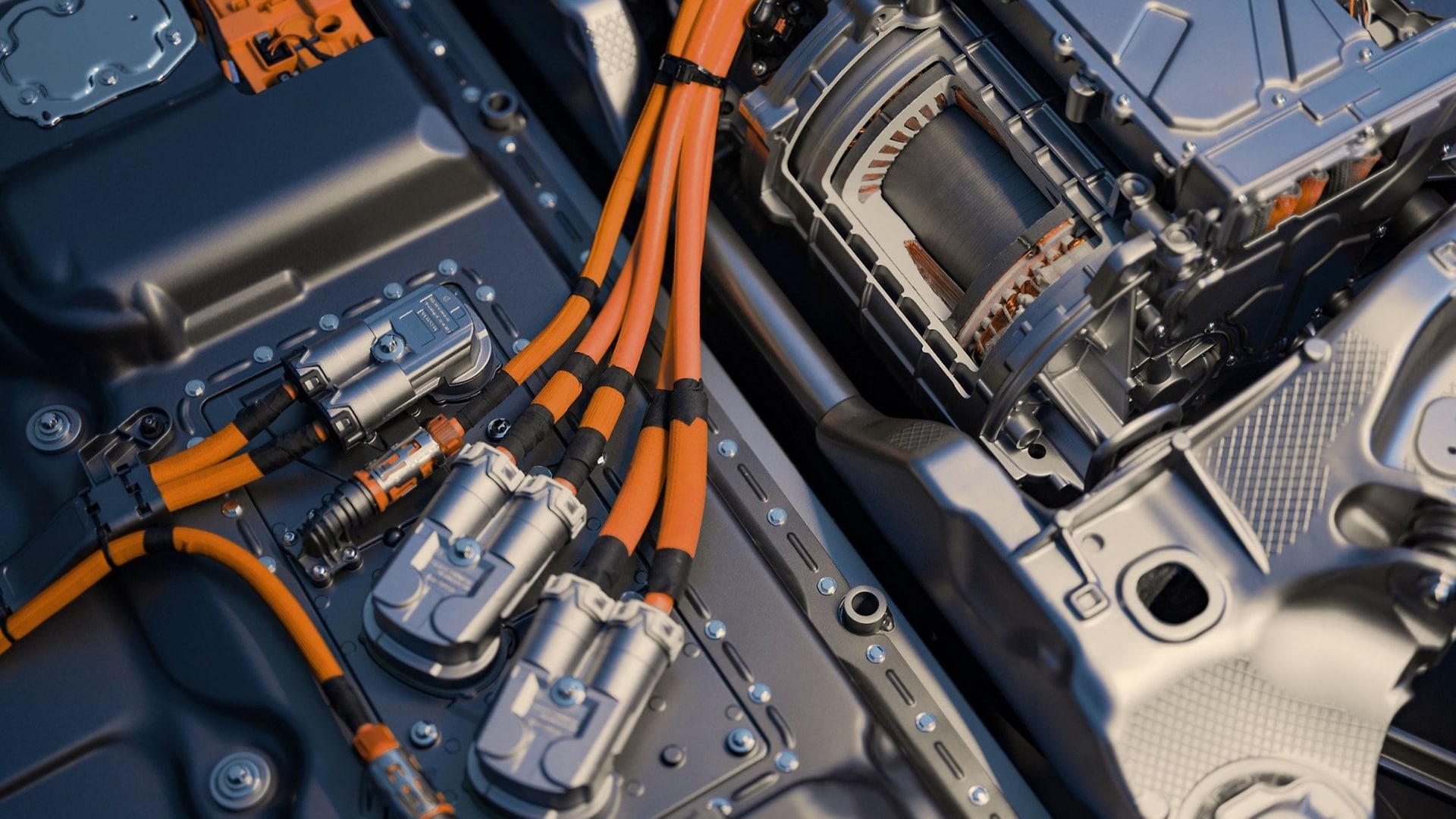

We rely on sustainable supply chains for our electric fleet and think about the responsible use of raw materials right from the start. Our goal is that our products contain only materials, raw and otherwise, that have been mined and produced without violating human rights and environmental standards. We therefore require our direct suppliers to comply with our Responsible Sourcing Standards (RSS) and to carry them into their upstream value chains as well as to monitor their compliance. The RSS apply worldwide and represent our code of conduct for the supply chain and include binding minimum requirements for suppliers. Mining auditing is another important tool to carry out due diligence in raw material supply chains and to address environmental and human rights risks that depend on the on-site management of the mine. In addition, Mercedes-Benz makes the “Standard for Responsible Mining” of the “Initiative for Responsible Mining Assurance” (IRMA) a key criterion for new supplier decisions and contracts in raw material supply chains and will only work with suppliers who agree to these requirements. As early as 2018, we commissioned RCS Global to create transparency along the complex cobalt supply chains of our battery cells and to check them against the OECD due diligence guidelines. In view of increasing requirements for due diligence and transparency in the supply chains of battery cells, we are not only continuing to implement audit and transparency measures in cooperation with RCS Global, but are also extending them from cobalt to the raw materials lithium, nickel, graphite, copper and manganese. In addition, the scope of human rights due diligence has been extended to environmental aspects such as biodiversity, water protection, hazardous substances and energy management.

For years, we have also been investing in resource-efficient technologies and manufacturing processes for batteries and are working to further reduce the use of critical materials. The cobalt content in the cathodes of the EQS battery cells, for example, is less than ten per cent and has been significantly reduced compared to the previous battery generation. In the future, we want to use post-lithium-ion technologies with new material compositions to completely eliminate materials such as cobalt. The further optimisation of recyclability and its implementation is also part of our holistic battery strategy.

More information on the handling of risk raw materials.

In addition, we address CO₂ emissions in our supply chain via the so-called “Ambition Letter”. For new contracts, we only accept suppliers who have confirmed that they will supply us with CO₂-neutral products from 2039 at the latest - and thus meet our climate targets. This means that only when the Ambition Letter has been signed suppliers do have a chance of being selected for the contract. In this way, we create a good basis for initiating actual reductions with our direct suppliers and in the supply chain. In 2023 suppliers representing 84 percent of Mercedes-Benz's annual purchasing volume have already signed an Ambition Letter, agreeing to supply us only with net carbon neutral production materials in the future.

Together with our suppliers, we are also working on a net carbon-neutral steel supply chain. By the end of the decade Mercedes-Benz aims to purchase more than 200,000 metric tons of CO₂-reduced steel annually from our European suppliers Salzgitter, thyssenkrupp Steel, voestalpine, Arvedi, SSAB and H2 Green Steel (H2GS) for our press shops. Already today, we are sourcing CO₂-reduced flat steel from Salzgitter Flachstahl GmbH. This is made from 100 percent scrap in an electric arc furnace. Moreover, we source CO₂-reduced steel from our Italian steel partner Arvedi. In September 2023, we also signed a supply agreement with Steel Dynamics, Inc. (SDI) for more than 50,000 metric tons of CO₂-reduced steel annually for our production plant in Tuscaloosa, Alabama. The steel supplied by SDI is produced in an electric arc furnace (EAF) that runs on 100 percent green electricity and has a scrap content of at least 70 percent. At the same time we are looking into CO₂-free steel: With our strategic partner H2 Green Steel (H2GS) we agreed on an annual purchase of around 50,000 tons of almost CO₂-free steel per year, which is to be used in various production models from mid of the decade. In 2022, In addition, we became the first passenger car manufacturer to receive steel from SSAB's hydrogen-based direct reduction. We intend to use almost CO₂-free steel from industrial production from 2026.

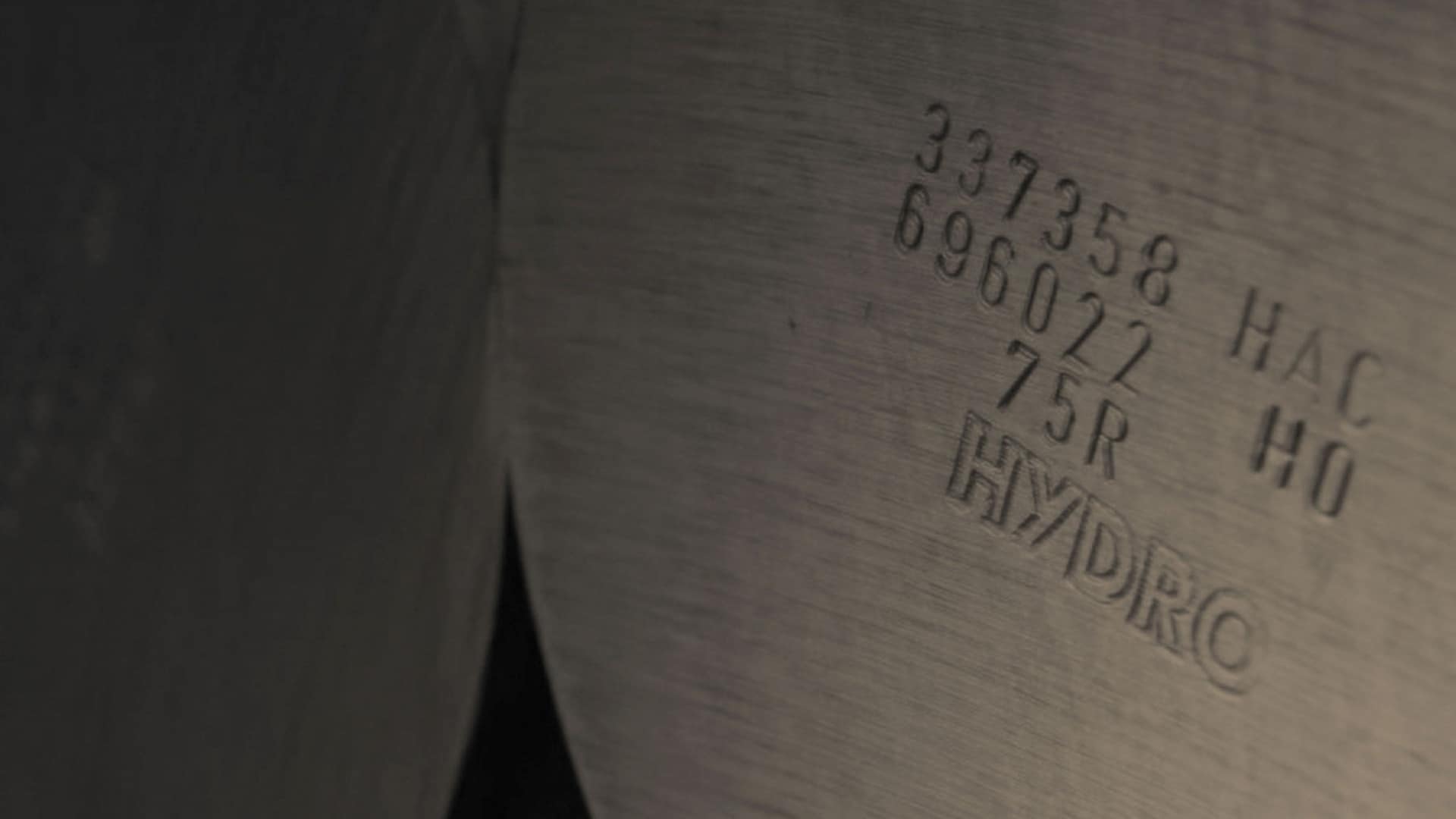

Aluminium, together with steel, is proportionally the most widely used material in many vehicles and is gaining in importance in electric vehicles. Therefore, we are also pursuing a clear roadmap of a carbon reduced aluminium supply chain – and have already reached important milestones.

In Europe, at least one third of the aluminium we use in our upcoming electric model generation is produced with renewable energy. Together with the Norwegian aluminium producer Hydro, we are going one step further and developing a technology roadmap to decarbonise the aluminium supply chain by 2030. Hydro is already supplying our foundry in Stuttgart Mettingen with CO₂-reduced aluminium. The strategic cooperation takes the collaboration to a new level: The first material from Norway with a CO₂ reduction of almost 70 percent compared to the European average and a scrap share of 25 percent has already been tested and has been used since 2023 in the series production of the EQS and EQE, among others. By 2030, we want to reduce the aluminium footprint with Hydro by more than 90 per cent with the help of new innovations. However, we are not only concerned with further reducing emissions. Another goal is to reduce the use of primary resources by increasing the use of secondary materials from post-consumer scrap.

,xPosition=0,yPosition=0.5)

,xPosition=0.5,yPosition=0)

,xPosition=1.0,yPosition=0)