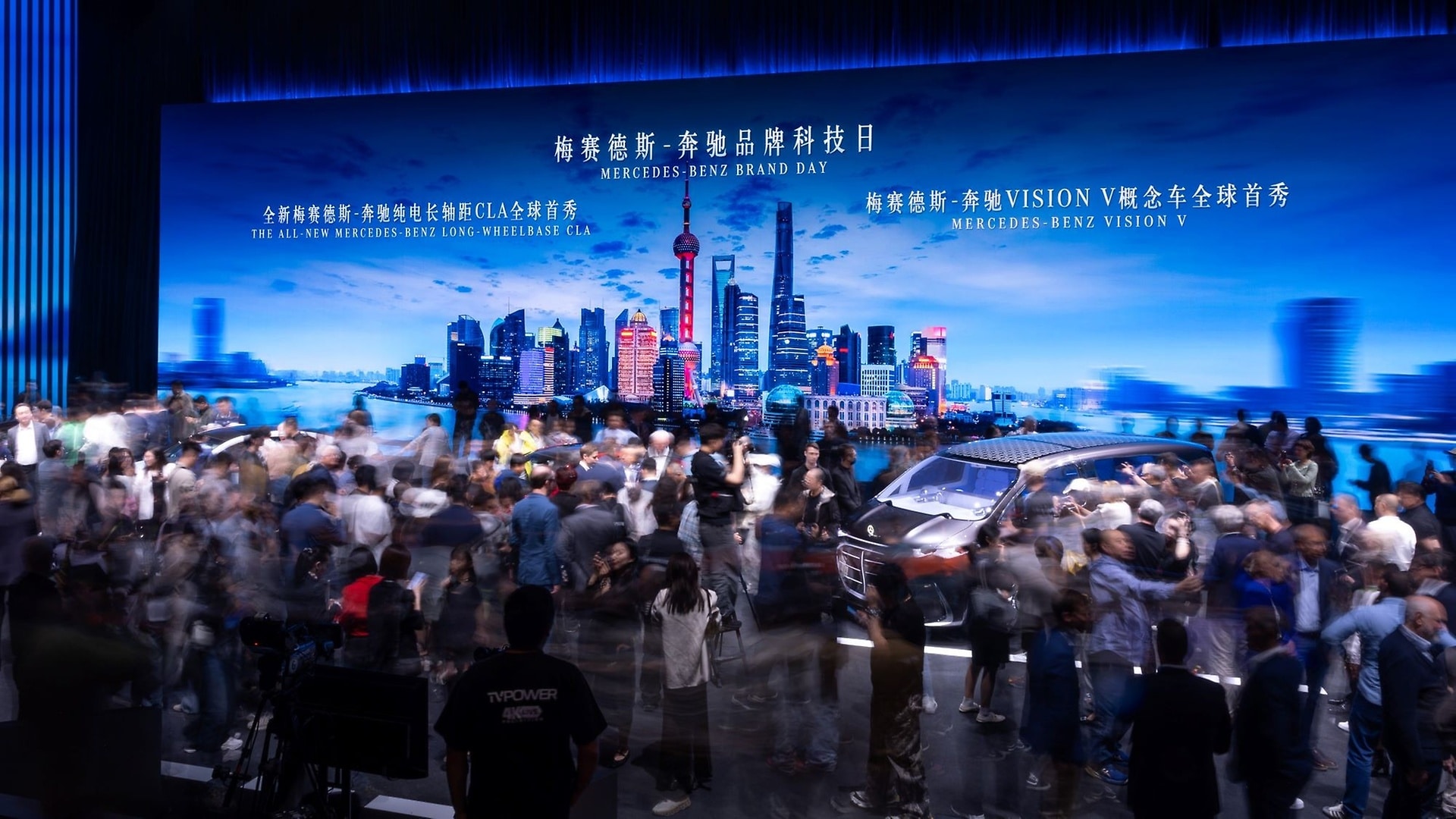

April 23, 2025 – With a plethora of China-specific vehicles and technologies planned for Auto Shanghai 2025, Mercedes-Benz is demonstrating its technical prowess and reaffirming its commitment to its biggest market.

,xPosition=0,yPosition=0)

Auto Shanghai 2025

Mercedes-Benz AG

Mercedesstraße 120

70372 Stuttgart

Germany

Phone: +49 7 11 17-0

E-Mail: dialog@mercedes-benz.com

Please send queries about content on this website to any contact. You can address your concerns to us in English and your respective national language.

Represented by the Board of Management:

Ola Källenius, Chairman; Jörg Burzer, Mathias Geisen, Olaf Schick, Michael Schiebe, Britta Seeger, Oliver Thöne, Harald Wilhelm

Chairman of the Supervisory Board: Martin Brudermüller

Court of Registry: Stuttgart; commercial register no. 762873

VAT ID: DE 32 12 81 763

All information about our products can be found on your country-specific Mercedes-Benz product page.

,xPosition=0,yPosition=0)

Auto Shanghai 2025

April 23, 2025 – With a plethora of China-specific vehicles and technologies planned for Auto Shanghai 2025, Mercedes-Benz is demonstrating its technical prowess and reaffirming its commitment to its biggest market.

China is home to Mercedes-Benz’s most comprehensive R&D hub outside Germany and 2025 marks the 20th anniversary of local production and tech activities in China. Oliver Thöne took up his first public appearance in his new role as member of the Board of Management of Mercedes-Benz Group AG.

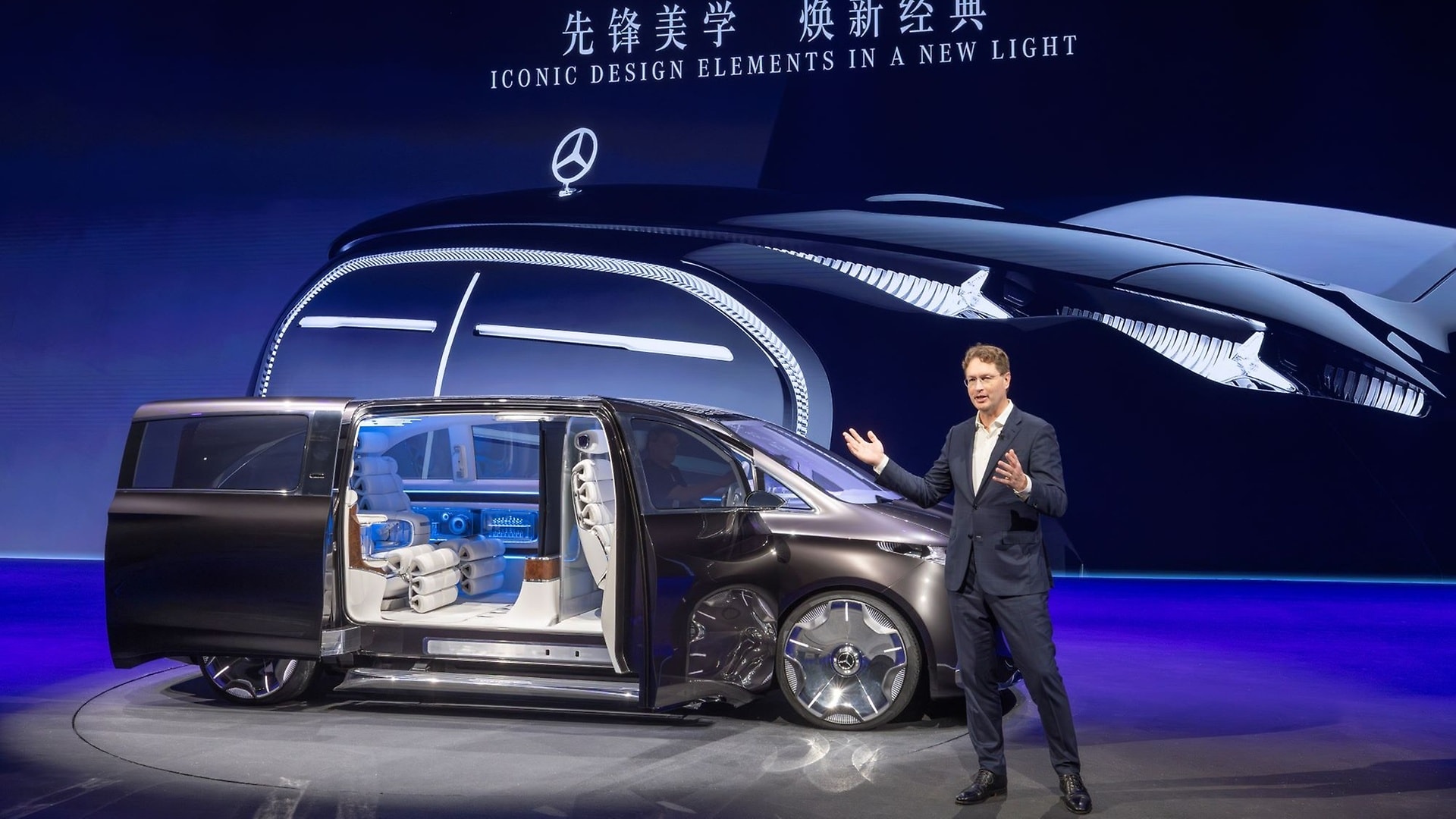

The Vision V

The introduction of the modular, flexible and scalable Van Architecture will usher in a new era starting in 2026. The future model portfolio will range from practical, entry-segment family vehicles and exclusive VIP shuttles to luxurious limousines with an enormous amount of space, each in line with different customer requirements. By expanding the top-end of its model portfolio, Mercedes-Benz is creating a unique segment of its own that defines automotive luxury. To underline this strategy, Mercedes-Benz is introducing a new naming format: The upcoming “Grand Limousines” will be called VLE and VLS.

With this variant, Mercedes-Benz is now offering customers in China more in every respect: more space, more visual sophistication, more comfort, more intelligence and more efficiency.

It is the first vehicle based on the scalable Mercedes-Benz Modular Architecture (MMA). It is also the first to operate on the new in-house developed Mercedes-Benz Operating System MB.OS, making it the first software-defined vehicle from Mercedes-Benz.

The electric version will offer a rear-mounted motor, a two-speed transmission and an 800-volt architecture. The electric range tops out at 866 kilometres according to CLTC (China Light-Duty Vehicle Test Cycle), which equals a consumption of 10.9 kWh/100 kilometres according to CLTC. Therefore, the long-wheelbase version also builds on the impressive efficiency of the Mercedes-Benz CLA

¹Mercedes-Benz CLA 250+ with EQ Technology: WLTP range of up to 792 kilometres and energy consumption of 14.1-12.2 kWh/100 kilometres

From 2026, Mercedes-Benz will be the first German car manufacturer to offer a production model with steer-by-wire technology. This system does not require a mechanical connection between the steering wheel and the front wheels. Instead, the driver’s steering input is transmitted quickly and directly via an electrical cable, i.e. “by wire”. The completely new steering setup ensures a unique customer experience because it reduces the effort required to turn the wheel from lock-to-lock and the cumbersome ‘hand-over-hand’ movements are eliminated. As a result, steer-by-wire makes low-speed manoeuvres and parking much easier. Driving dynamics also benefit because the Mercedes-Benz chassis specialists can select the steering ratio in a completely variable manner and adapt it flexibly to different situations.

Mercedes-Benz is providing exclusive insights into ongoing research activities aimed at automotive progress far beyond the current period of transformation – innovations for a completely new era of mobility. This includes the development of groundbreaking technologies for a better quality of life and road safety, for more climate protection and resource conservation and for more digital experiences that are hyper-personalised and extend far beyond the vehicle.

Through research into artificial neural networks, Mercedes-Benz and its partners from research and industry are breaking new ground in the creation of computer architectures. The company recently announced a research collaboration with the Canadian University of Waterloo in the field of neuromorphic computing. By mimicking the workings of the human brain, neuromorphic computing could make AI computations significantly more energy-efficient and faster. Safety systems could, for example, recognise traffic signs, lanes and other road users much better and react faster, even in poor visibility. And they could do so 10 times more efficiently than current systems. It has also the potential to reduce the energy required for data processing in autonomous driving by 90 percent compared to current systems.

Mercedes-Benz is researching new types of solar modules that could be seamlessly applied to the bodywork of electric vehicles – similar to a wafer-thin layer of paint that could generate enough electricity to power the vehicle for over 14,000 km per year (under ideal conditions, based on the light incidence in Beijing/China). The active photovoltaic surface can be applied to any substrate. The solar cells have an efficiency of 20 percent and are therefore highly efficient. The solar paint could be a very effective future solution for longer ranges and fewer charging stops.

Mercedes-Benz is also striving for a paradigm shift in the use of a new generation of power electronics technologies in electric vehicles. In future, a programmable micro-converter could go beyond the limits of current electrical inverter systems and revolutionise existing high-voltage architectures. The basis for this is the integration of these micro-converters directly at battery-cell level, which could enable individual control of battery-cell pairs, as well as communication between cells.

As electric vehicles brake primarily through recuperation, Mercedes-Benz is entering completely new territory in the development of mechanical brakes. The innovative, more sustainable brake that is currently under research is no longer in the typical location at the wheel. It takes up very little installation space, hardly wears out and is virtually maintenance-free. This makes it very durable and reliable. In addition, the braking effect is easy to control and does not diminish even under high loads. Thanks to integration into the closed motor-transmission unit, no particulate emissions from brake abrasion reach the outside and the brake does not rust. This could prevent brake noise in the future. There would also be no need to clean the brakes. Clean brakes have a positive effect on efficiency and range.