September 23, 2022 – "Mercedes-Benz Digital Factory Campus," the competence center for digitalization in the global Mercedes-Benz production network, officially starts operations.

,xPosition=0,yPosition=0.5)

Berlin Marienfelde

Mercedes-Benz AG

Mercedesstraße 120

70372 Stuttgart

Germany

Phone: +49 7 11 17-0

E-Mail: dialog@mercedes-benz.com

Please send queries about content on this website to any contact. You can address your concerns to us in English and your respective national language.

Represented by the Board of Management:

Ola Källenius, Chairman; Jörg Burzer, Mathias Geisen, Olaf Schick, Michael Schiebe, Britta Seeger, Oliver Thöne, Harald Wilhelm

Chairman of the Supervisory Board: Martin Brudermüller

Court of Registry: Stuttgart; commercial register no. 762873

VAT ID: DE 32 12 81 763

All information about our products can be found on your country-specific Mercedes-Benz product page.

,xPosition=0,yPosition=0.5)

Berlin Marienfelde

September 23, 2022 – "Mercedes-Benz Digital Factory Campus," the competence center for digitalization in the global Mercedes-Benz production network, officially starts operations.

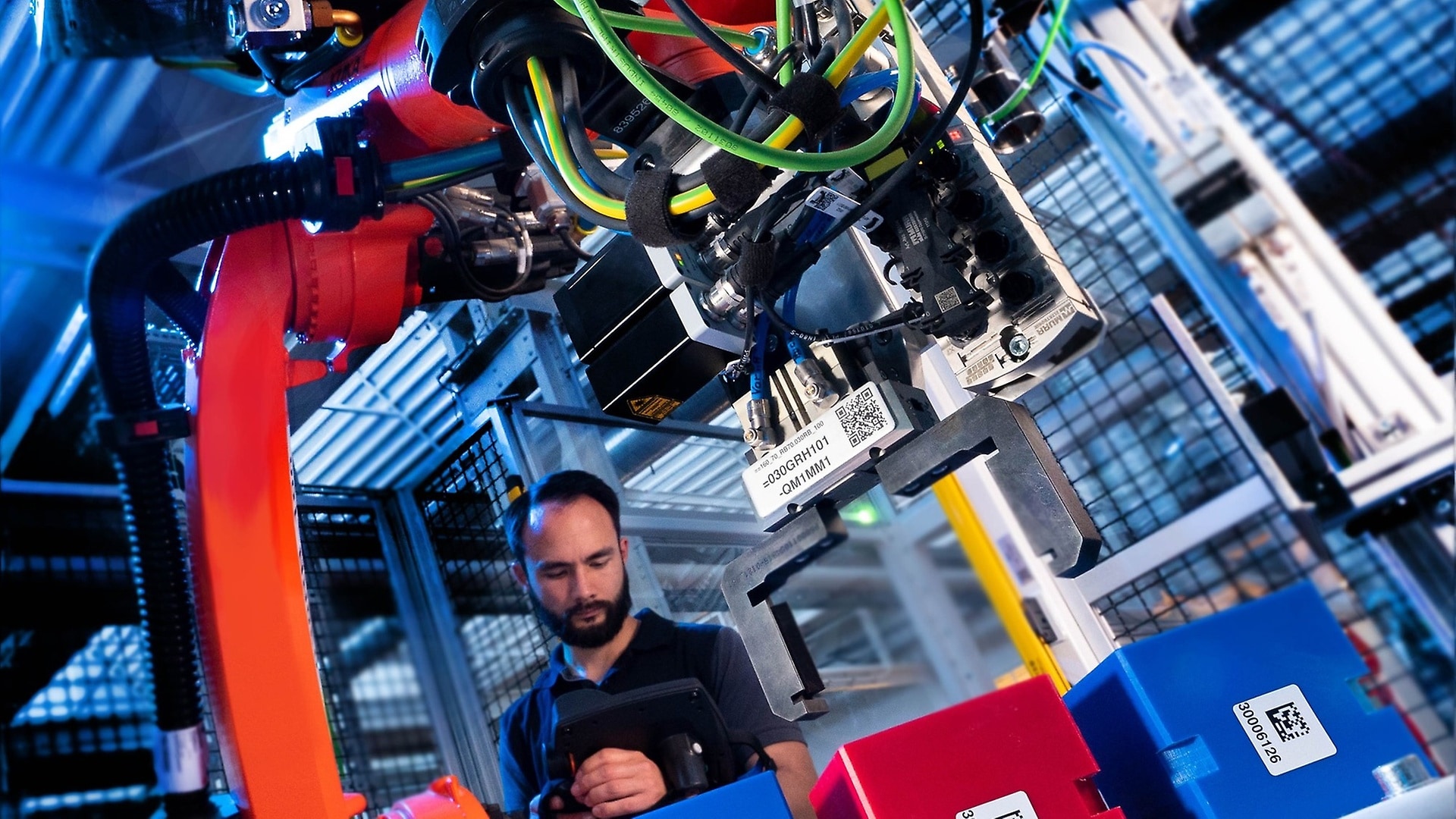

Mercedes-Benz AG opened its Mercedes-Benz Digital Factory Campus (MBDFC) marking the transformation of its Berlin-Marienfelde site into a centre for digitalization in automotive production. With a series of state-of-the-art pilot lines and test cells, the campus is now a hub for global Mercedes-Benz digital production technologies, combining development, testing, and seamless and rapid global implementation of pioneering MO360 software applications for automotive production as well as acting as a digital start-up factory. In addition, the campus will become the MO360 training and qualification center for implementing digital approaches in the global network. With the MBDFC and the production of electric drive components, the site forms an important pillar of the Mercedes-Benz "electric only" strategy. Mercedes-Benz is investing a triple-digit million euros amount into the transformation of Berlin-Marienfelde over the next five years.

The digitalization of production is a key success factor for Mercedes-Benz. Through the introduction and consistent further development of MO360, the digital ecosystem, all core production processes have already been standardized, digitized and rolled out worldwide in all Mercedes-Benz plants. This ensures maximum efficiency, transparency and sustainability in a geopolitically increasingly volatile and challenging environment.

As a competence center for the digitalization of IT-based production, the Mercedes-Benz Digital Factory Campus is driving the development, testing and validation of future software applications and concepts for MO360 - in a real production environment. In the body shop, assembly as well as in technology cells, production processes are replicated and new features and software updates are tested before being transferred to real production lines. Virtual methods are combined with real-world validation. This shortens development time and increases robustness.

The Mercedes-Benz Digital Factory Campus is also an MO360 Training and Qualification Center, where innovative training programs are developed for the entire Mercedes-Benz production network. Targeted qualification concepts are an important prerequisite for successfully managing the electrification and digitalization of the working world in both production and administration.

The digital learning platform LES, the Learning Environment System, which was developed at MBDFC and implemented at Mercedes-Benz Operations, offers the optimal attachment point for the work of colleagues thanks to its maximum flexibility.

Electrification and digitalization in the automotive industry are bringing changes to production and to all job profiles. With Turn2Learn, the company has launched a comprehensive qualification offensive to make employees fit for this transformation. For production employees, for example, the company offers specially tailored digital retraining with individual support and defined target positions. Following an initial successful pilot project in which employees - the so-called "Digital Pioneers" - from the Berlin plant, continue on their individual journey towards the career goal of "Junior Software Developer."Retraining continues in the Mercedes-Benz Powertrain plant in Untertürkheim, where "Digital Superheroes" from production and production-related areas, started their in-service qualification as Data Specialist in June. A special retraining program for Mercedes-Benz Operations is offered under the name D.SHIFT. D.SHIFT is part of the Mercedes-Benz qualification offensive Turn2Learn with a focus on production and puts the focus on the further training of digital competencies of employees. D.SHIFT describes the path of each individual in the transformation to the digital future.

With its broad offering geared towards IT-based production, the Mercedes-Benz Digital Factory Campus also relies on cooperation with partners from business and science; for example, with universities, research institutions and innovative industrial companies. Mercedes-Benz and Siemens, with the support of the State of Berlin, have already been working together on the sustainable digitalization and automation of the automotive industry since 2021. As a leading provider in the field of automation, industrial software and intelligent infrastructure, Siemens is contributing its expertise and technologies to the partnership for this purpose, in order to develop highly flexible, efficient and sustainable automotive production together with Mercedes-Benz. Optimized algorithms in the applied robotics of the production lines make it possible to operate more energy-efficiently and reduce production times.