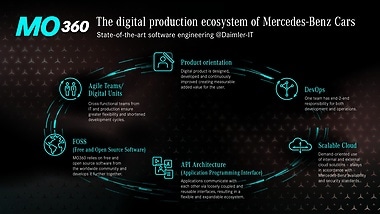

What are the major components that individually make up MO360?

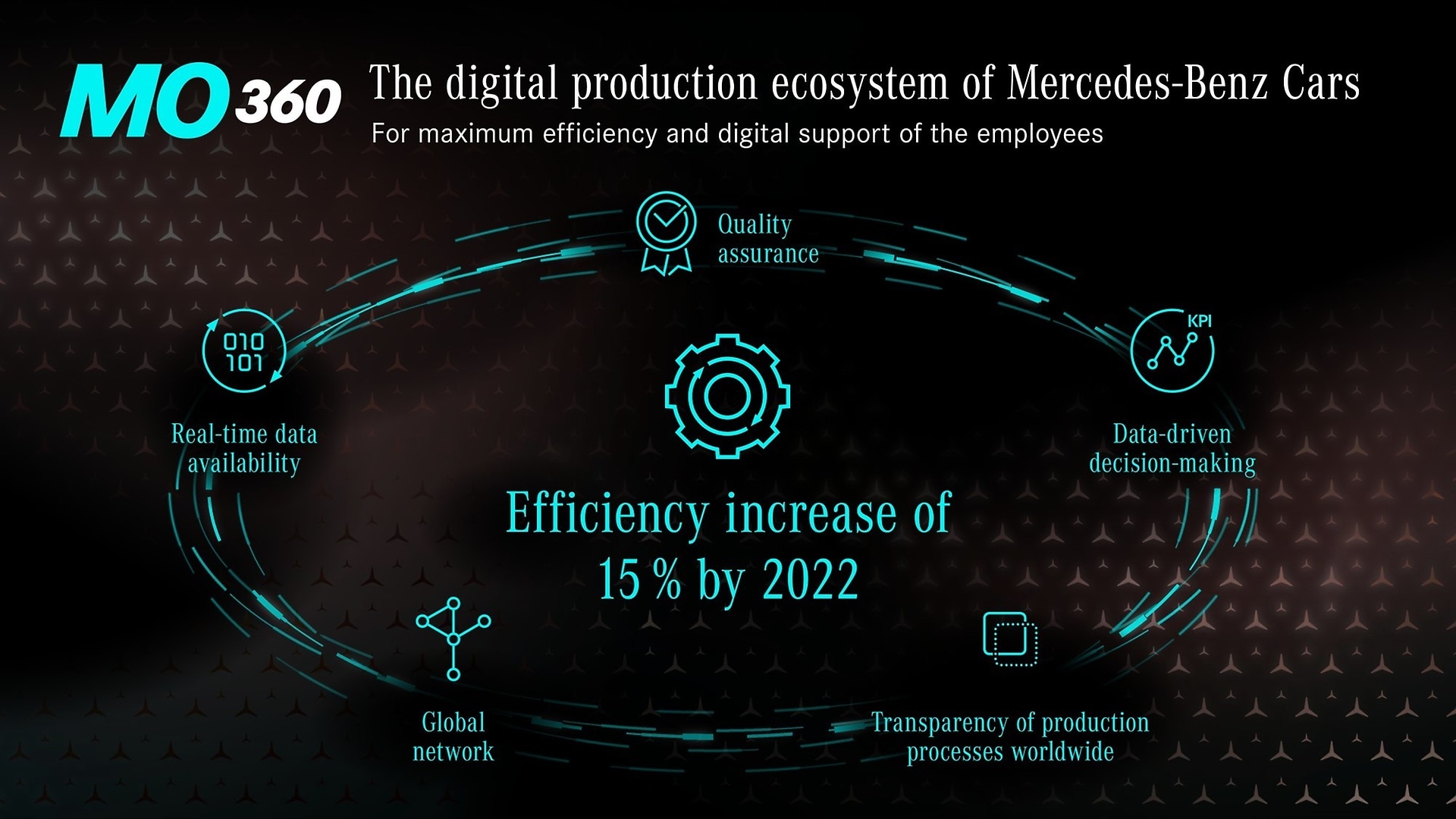

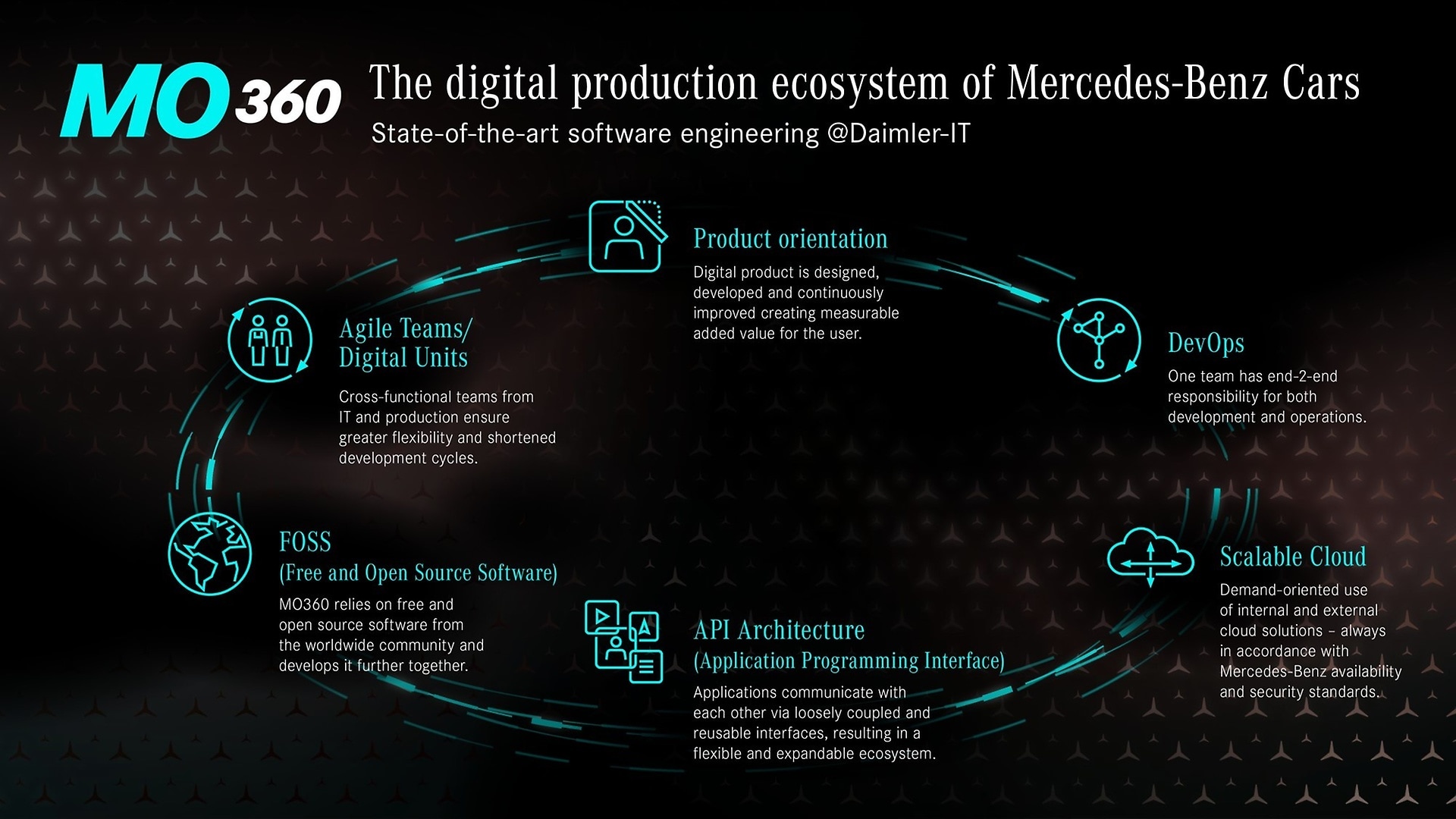

Jörg Burzer: The new, digital eco-system comprises a number of software applications. Two applications that are already fully integrated into MO360 are dedicated to quality assurance (QUALITY LIVE) and production management (Shopfloor Management digital, SFMdigital). These two applications have already been introduced in practically all Mercedes-Benz Cars plants around the world. Another element of MO360 is digital communication and support for production employees using the PAPERLESS FACTORY system. Printed lists and the vehicle configuration card are now things of the past, for example. This will set new standards in terms of efficient production.

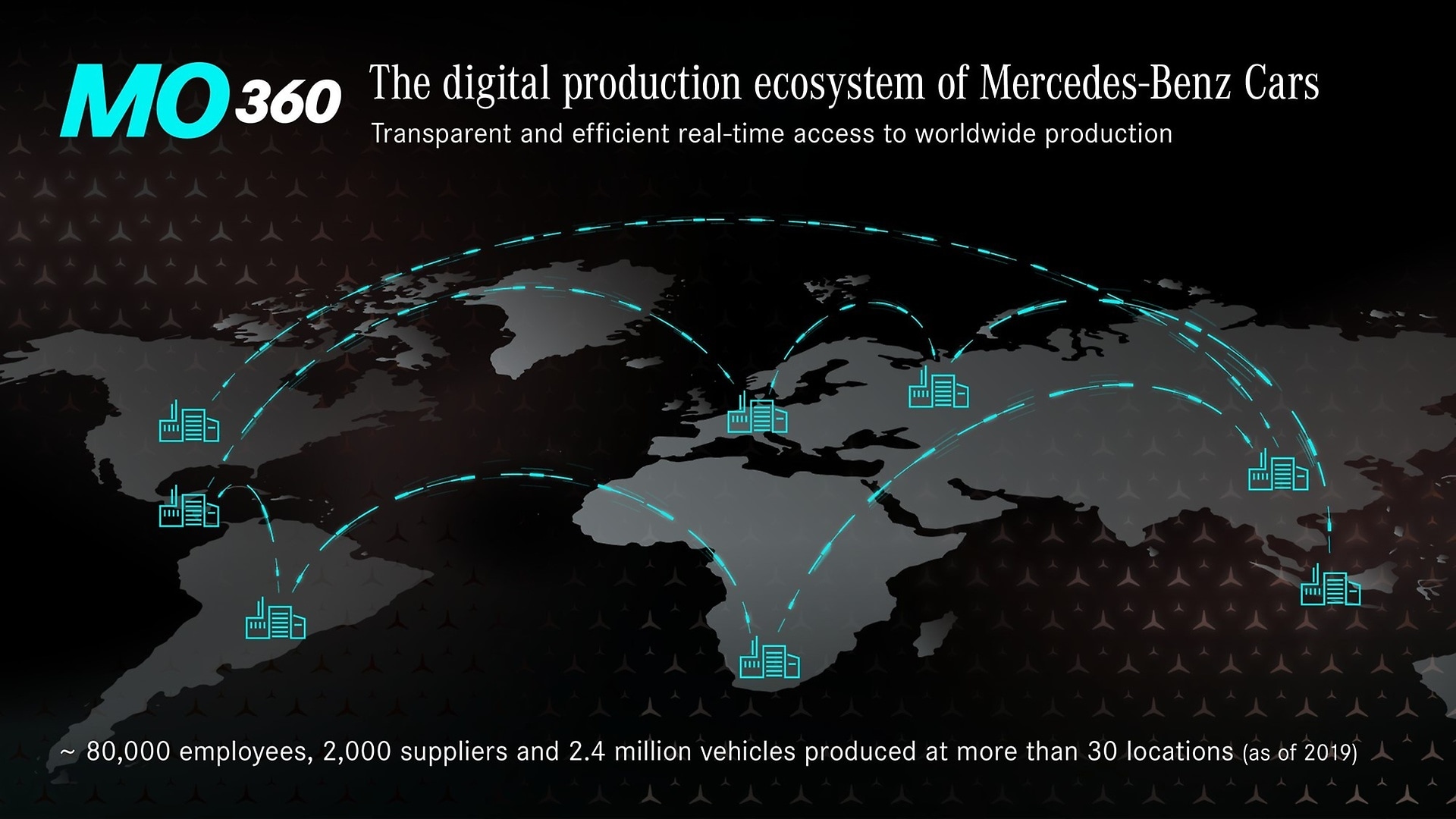

Jan Brecht: As Jörg has already said, many elements of MO360 are already in use in our more than 30 car plants around the world. On the one hand, our Integra standard helps us, through which we can easily access the data of our production facilities. On the other hand, we have a very uniform IT landscape, even when compared to the competition, so that we can quickly get our MO360 rolled out worldwide.

,xPosition=0,yPosition=0.5)

,xPosition=0.5,yPosition=0)