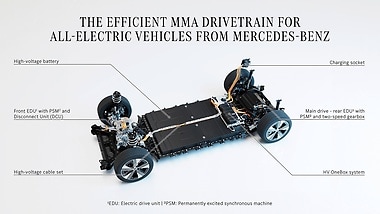

The EDU 2.0 reconciles the conflicting goals of maximum torque, top speed and exemplary efficiency, especially in real driving conditions. This is because the high torque ensures dynamic driving performance. It is also helpful when negotiating mountain passes or towing trailers. Another strength is the extraordinary compactness of the EDU 2.0, which benefits the interior dimensions and the volume of the rear boot.

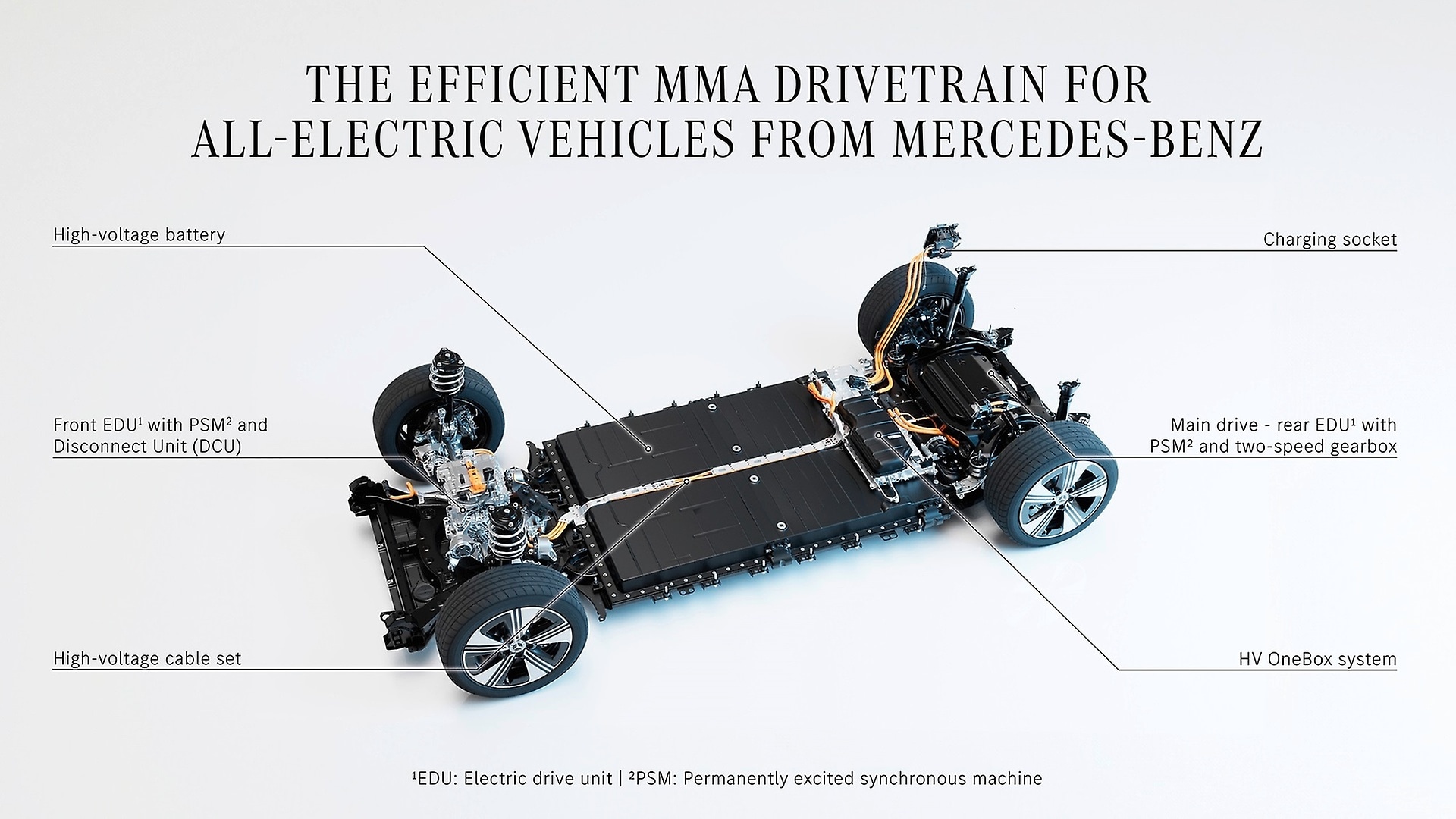

The 4MATIC models also have an 80-kW drive unit on the front axle. In the interests of efficiency, this is also equipped with a next-generation inverter with silicon carbide (SiC) and designed as a permanently excited synchronous machine (PSM). The front electric motor acts as a “boost” drive. Depending on the driving situation or driving programme, it is only switched on when the corresponding power or traction is required. This task is performed by the Disconnect Unit (DCU), which Mercedes-Benz is now using for the first time in the entry-level segment.

,xPosition=0,yPosition=0.5)

,xPosition=1.0,yPosition=0)