The VISION EQXX research prototype is a vehicle designed specifically for the transformative journey into electromobility.

,xPosition=0,yPosition=0.5)

Taking electric range and efficiency to an entirely new level

Mercedes-Benz AG

Mercedesstraße 120

70372 Stuttgart

Germany

Phone: +49 7 11 17-0

E-Mail: dialog@mercedes-benz.com

Please send queries about content on this website to any contact. You can address your concerns to us in English and your respective national language.

Represented by the Board of Management:

Ola Källenius, Chairman; Jörg Burzer, Mathias Geisen, Markus Schäfer, Olaf Schick, Britta Seeger, Oliver Thöne, Harald Wilhelm

Chairman of the Supervisory Board: Martin Brudermüller

Court of Registry: Stuttgart; commercial register no. 762873

VAT ID: DE 32 12 81 763

All information about our products can be found on your country-specific Mercedes-Benz product page.

,xPosition=0,yPosition=0.5)

Taking electric range and efficiency to an entirely new level

The VISION EQXX research prototype is a vehicle designed specifically for the transformative journey into electromobility.

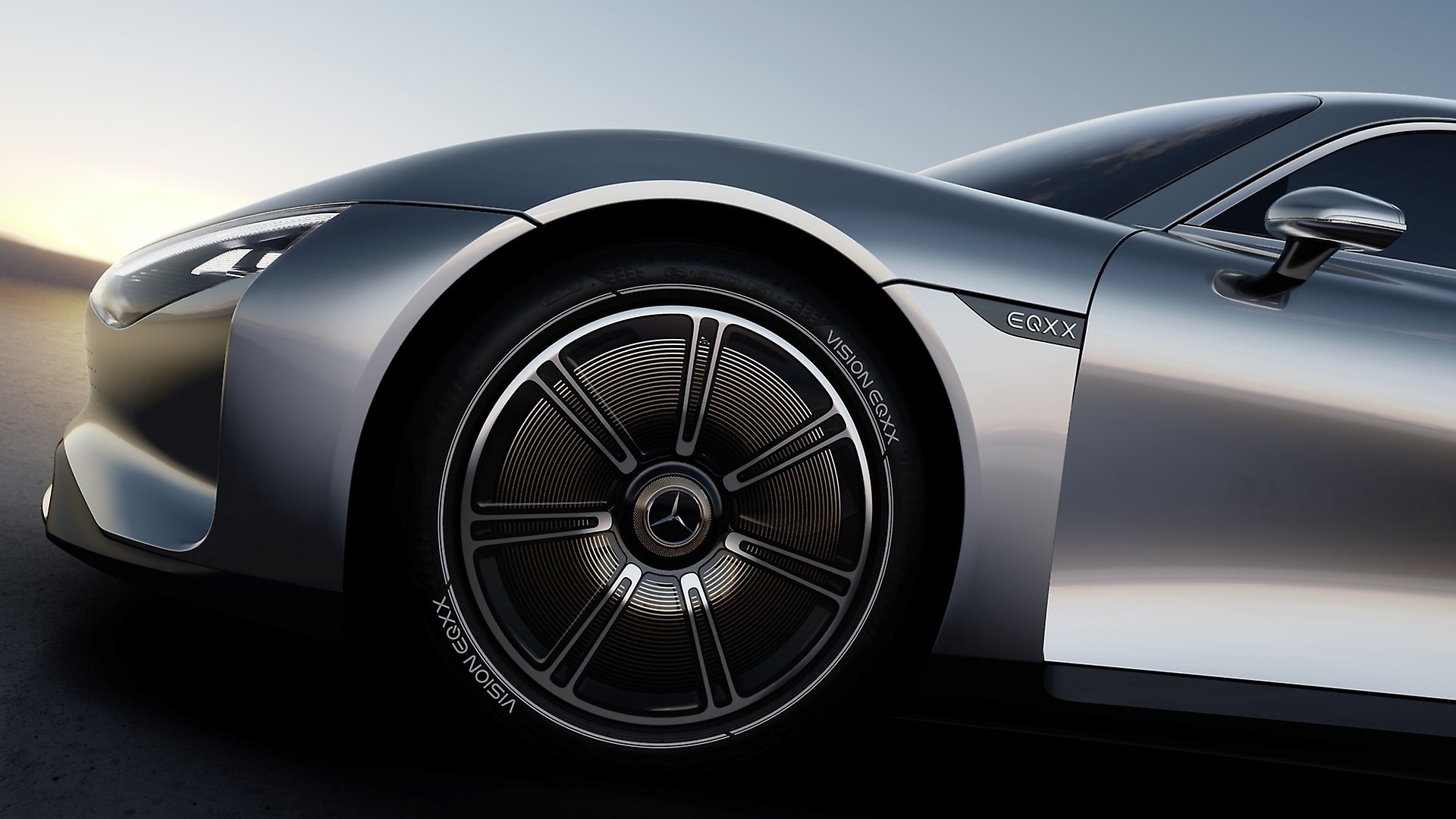

With more than 620 miles¹ (1,000 km) of real-world electric range on a single charge and energy consumption of less than 10 kWh/100 km, the VISION EQXX is a blueprint for the future of efficiency. Beyond the exceptional achievements of its highly advanced drivetrain, impressive drag coefficient of 0.17 and lightweight bionic design, the VISION EQXX is also a masterclass in a radically new software-driven approach to the UI/UX. A game engine elevates the UI graphics to a whole new level of digital luxury. The user interface shows how real-time graphics opens up entirely new digital possibilities, reacting immediately to the driver’s needs and bringing the real world into the vehicle. This human machine merge creates a true partnership between car and driver. This increasingly seamless relationship is further facilitated with intuitive interaction via the highly efficient yet visually striking one-piece display. Meanwhile, through machine learning, a more characterful, emotional voice for “Hey Mercedes” places the conversation between driver and car on a whole new and more natural level.

The innovations of the VISION EQXX serve as a blueprint for future Mercedes-Benz vehicles and offer luxury that can be experienced through sustainable materials such as animal-free leather alternatives. Mercedes-Benz has also set new records for aerodynamics and weight reduction and developed a software-based vehicle concept with a focus on long-distance efficiency and resource-saving design. The VISION EQXX interprets modern luxury and sensual clarity in a progressive way.

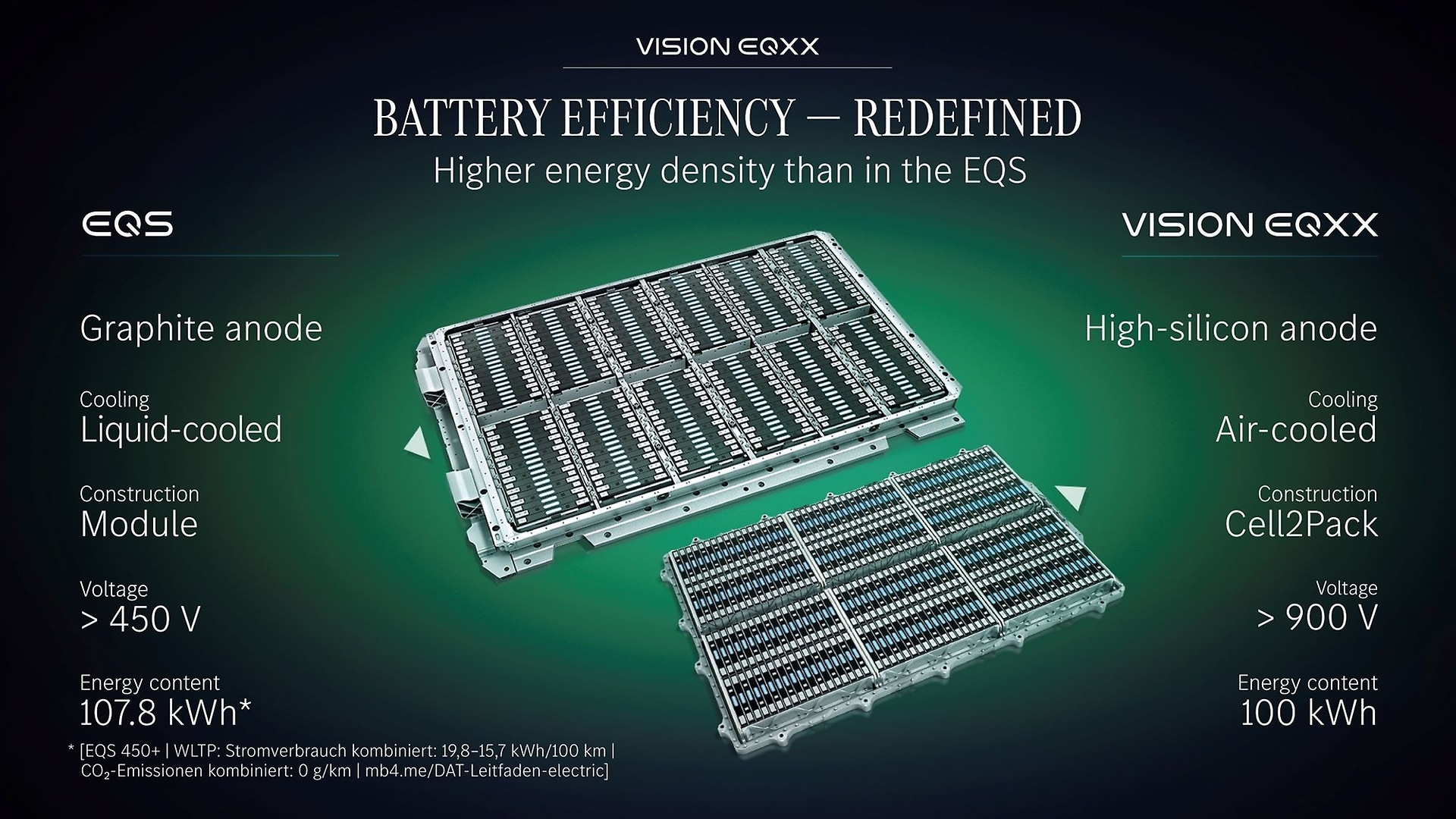

| Battery energy content | <100 kWh |

|---|---|

| Rated voltage | >900 Volts |

| Cd value | 0.17 |

| Front face | 2.12 m² |

| Power | 180 kW |

| Wheelbase | 2,800 mm |

| Length/width/height | 4,975/1,870/1,348 mm |

| Unladen vehicle weight | 1,755 kg |

The Mercedes-Benz VISION EQXX is how we imagine the future of electric cars. Just one-and-a-half years ago, we started this project leading to the most efficient Mercedes-Benz ever built – with an outstanding energy consumption of less than 10 kWh per 100 kilometres. It has a range of more than 1,000 kilometres¹ on a single charge using a battery that would fit even into a compact vehicle. The VISION EQXX is an advanced car in so many dimensions – and it even looks stunning and futuristic. With that, it underlines where our entire company is headed: We will build the world’s most desirable electric cars.

Ola Källenius

Chairman of the Board of Management of Daimler AG and Mercedes-Benz AG

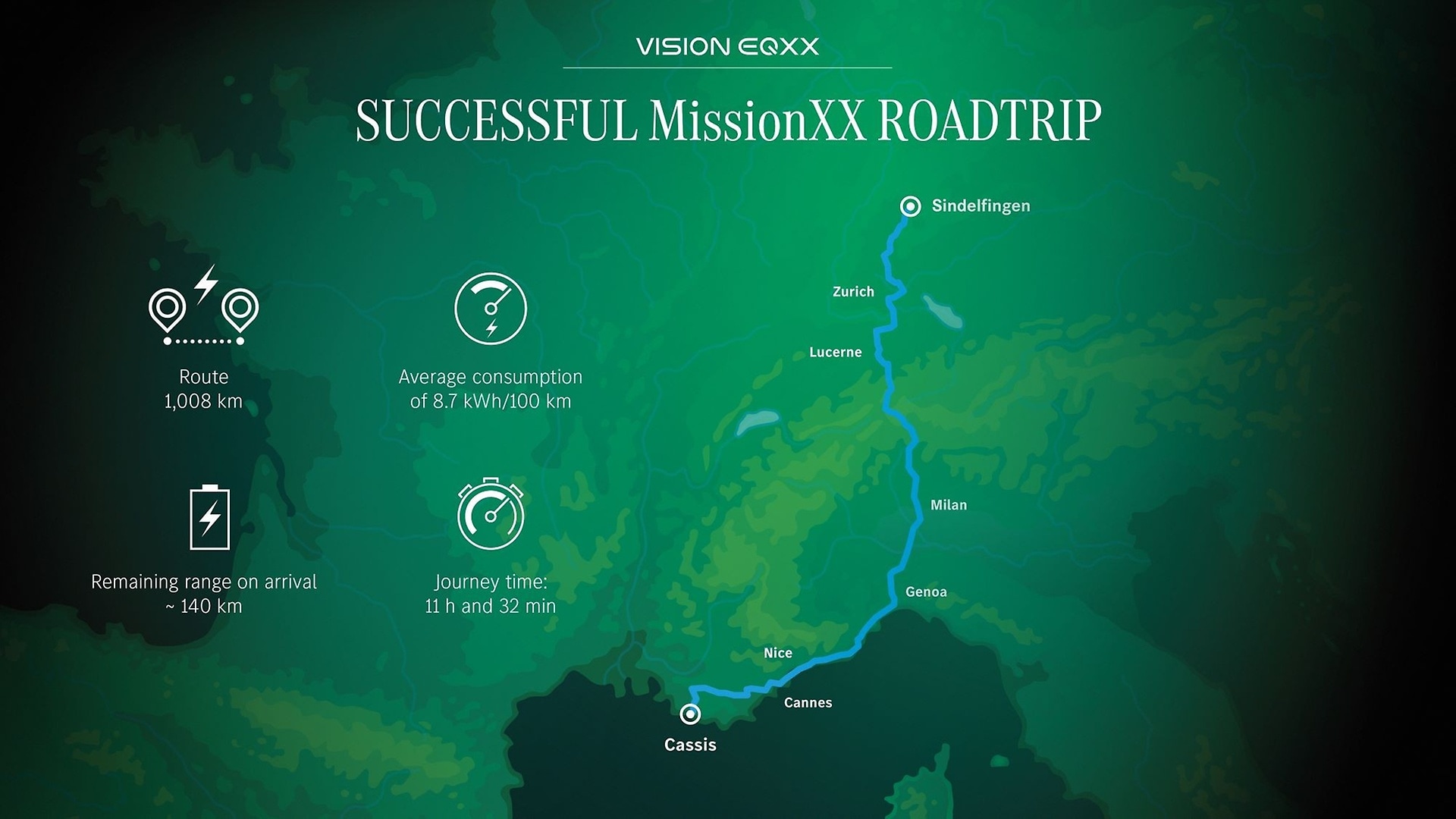

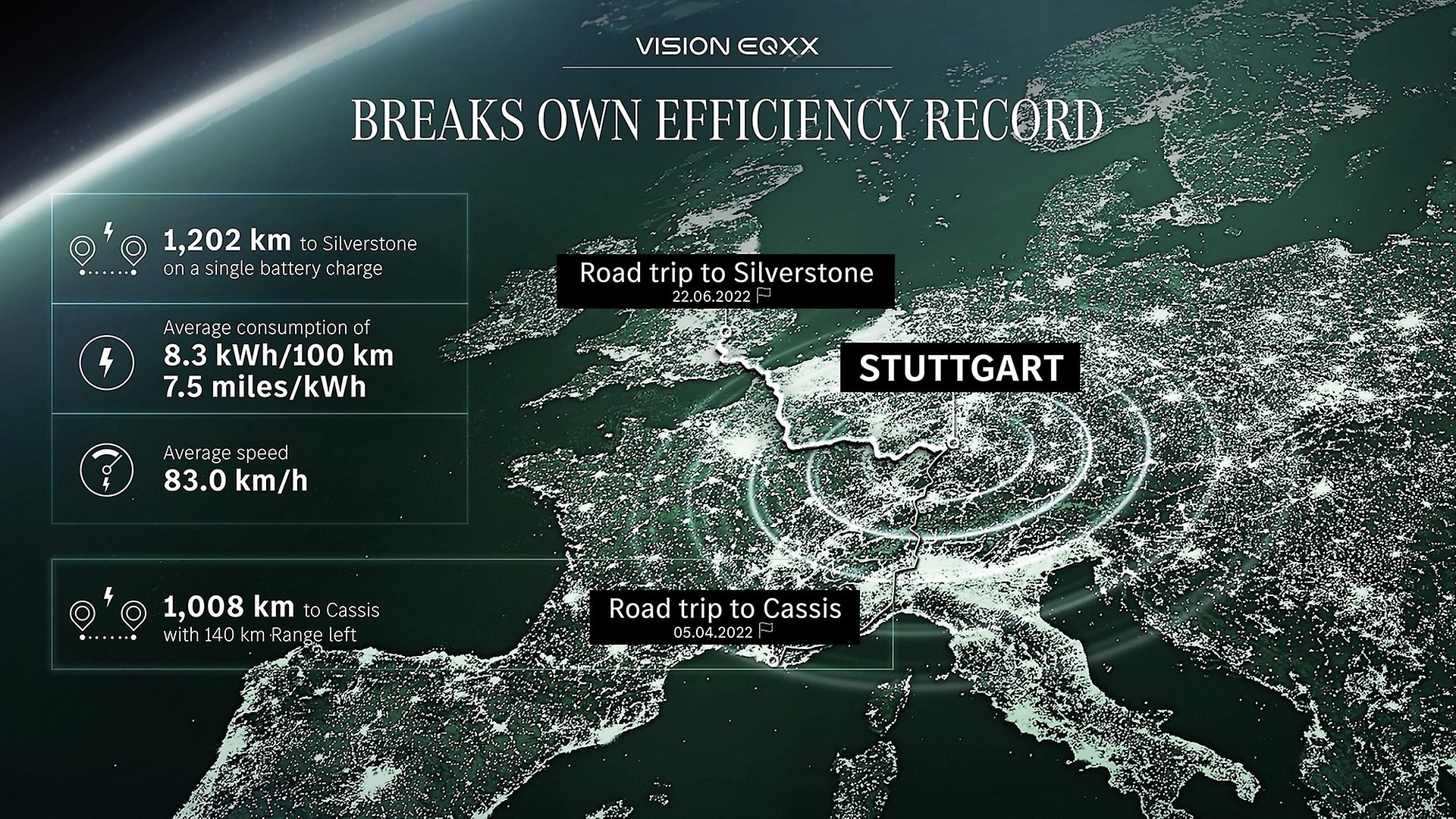

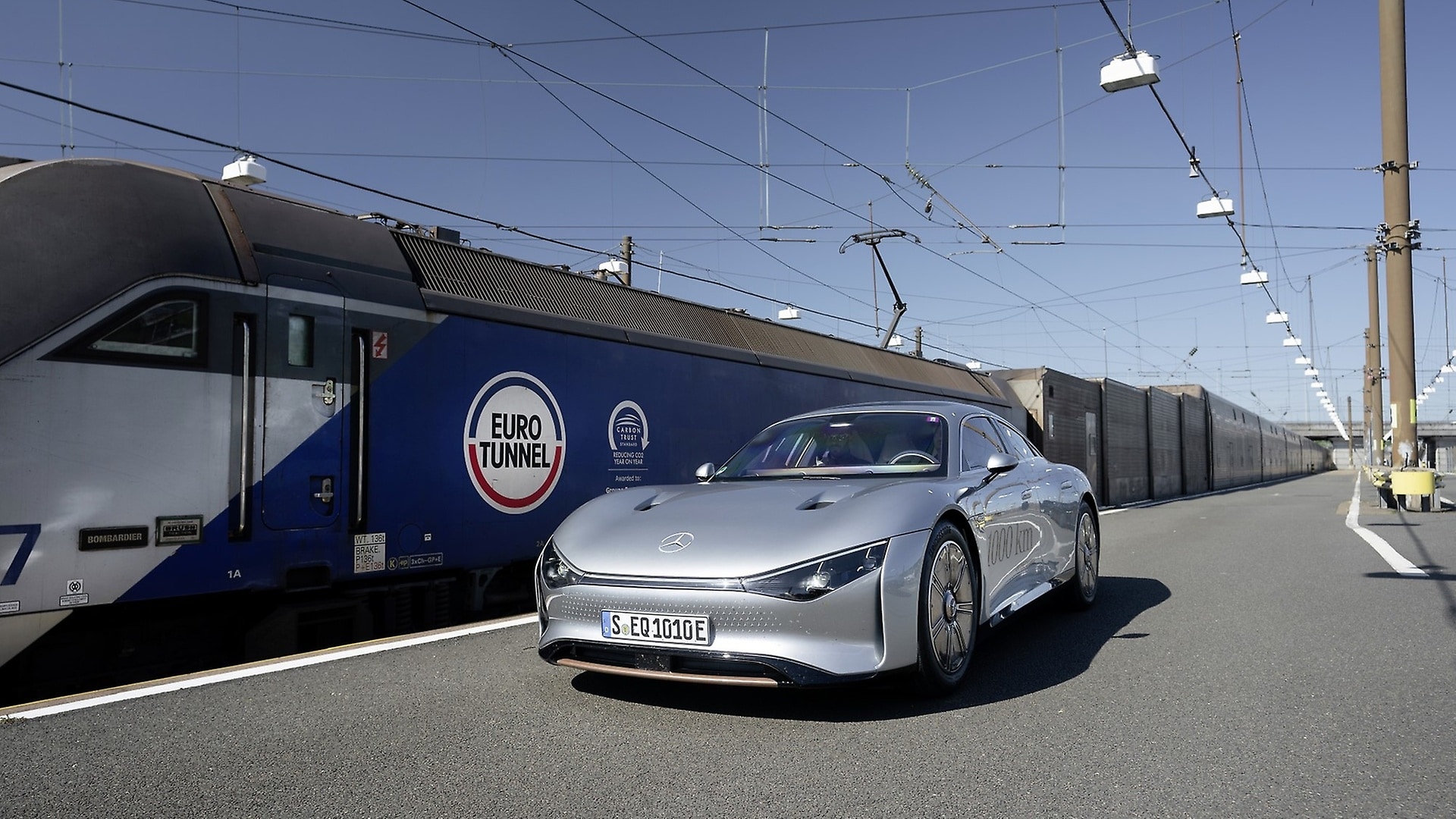

On a total of three long-distance journeys, Mercedes-Benz has proven the practicality of this visionary vehicle and exceeded its own efficiency record. The VISION EQXX completed its first long-distance journey in real road traffic in April 2022. Further journeys, each with more than 1,000 kilometres, followed in June 2022 and March 2024.

| Start | Sindelfingen, April 5th, 2022, 7:00 a.m. |

|---|---|

| Arrival | Cassis, April 5th, 2022, 7:02 p.m. |

| Travel route | Sindelfingen, Gotthard Tunnel, Milan, Cassis |

| Driving distance | 1,008 kilometres |

| Total travel time/movement | 12 hours and 2 minutes/11 hours and 32 minutes |

| Average speed | 87.4 km/h |

| Maximum speed on motorway | 140 km/h |

| Average consumption | 8.7 kWh per 100 km |

| Battery charge level on arrival (SoC) | around 15% |

| Remaining range on arrival | around 140 km |

| Start | Sindelfingen, April 5th, 2022, 7:00 a.m. |

|---|---|

| Arrival | Cassis, April 5th, 2022, 7:02 p.m. |

| Travel route | Sindelfingen, Gotthard Tunnel, Milan, Cassis |

| Driving distance | 1,008 kilometres |

| Total travel time/movement | 12 hours and 2 minutes/11 hours and 32 minutes |

| Average speed | 87.4 km/h |

| Maximum speed on motorway | 140 km/h |

| Average consumption | 8.7 kWh per 100 km |

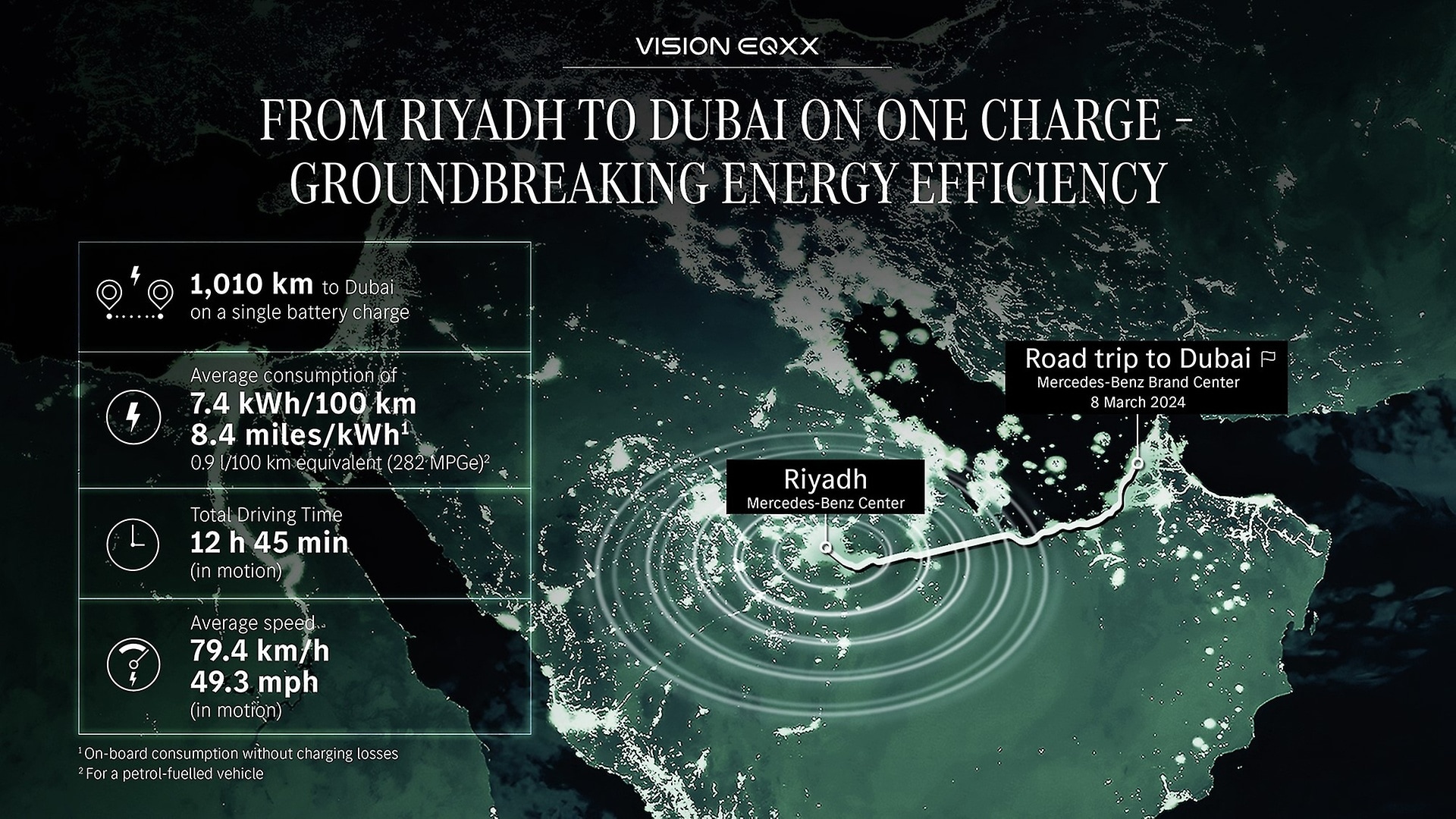

| Start | Mercedes-Benz Center, Riyadh, 8 March 2024, 4:15 a.m. (AST) |

|---|---|

| Arrival | Mercedes-Benz Brand Center, Dubai, 8 March 2024, 7:57 p.m. (GST) |

| Travel route | Riyadh, Haradh, Al Batha, Abu Dhabi, Dubai |

| Driving distance | 1,010 km (627.6 miles) |

| Total travel time | 14:42 h |

| Average speed | 68.7 km/h (42.7 mph) including vehicle static (1:57 h due to border crossing and driver change); 79.4 km/h (49.3 mph) in motion |

| Maximum speed on motorway | 140 km/h (87 mph) |

| Average consumption | 7.4 kWh/100km (8.4 mi/kWh)¹, equalling around 0.9 l/100 km or 282 MPGe for a petrol-fuelled vehicle |

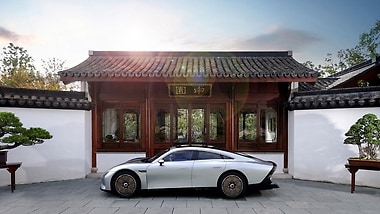

More than two years after it was unveiled, the VISION EQXX has covered more than 25,000 kilometres (15,534 miles) testing its pioneering electric technology under a wide range of demanding real-life conditions. In a region often associated with super sports cars and full-size SUVs, the compact dimensions and sleek proportions of the VISION EQXX drew intense interest. The slippery drag coefficient of just 0.17 pairs with a sophisticated fastback design to represent a highly desirable ambassador for electric mobility. Likewise, with charging infrastructure still sparse in many parts of the world, this was a valuable opportunity to demonstrate long-range electric efficiency under real-life conditions. Another important aspect of the Mercedes-Benz electrification strategy.

In addition to the two previous road trips in Europe, Mercedes-Benz has also taken the VISION EQXX to audiences in the US and China. This has given key global target groups the chance to experience for themselves a realistic, road-going example of luxurious and sustainable electric efficiency.

¹Range figures preliminary and based on digital simulations in real-life traffic conditions. The VISION EQXX has not undergone type approval or homologation

²On-board consumption without charging losses.

This article was last updated in Oktober 2025.