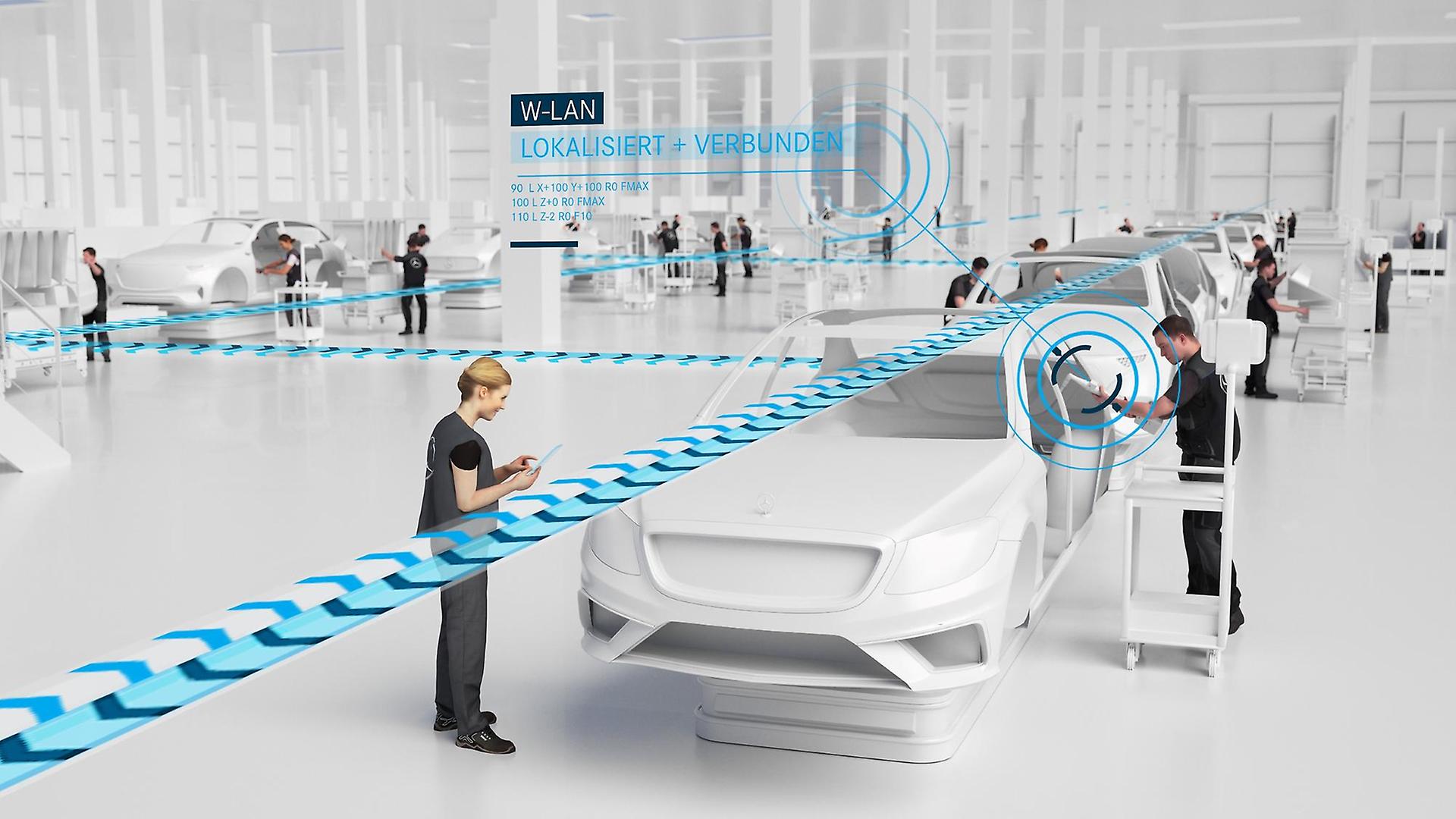

However, networking not only happens inside the factory. A significant feature of "Factory 56" is the all-round networking across the entire value-added chain – from development and design to suppliers, production and customers. In coordination with our suppliers, we use the benefits of tracking and tracing, for example, which allows load carriers to be traced digitally around the world. Tracking and tracing enables early detection of discrepancies in the supply chain and thus a quicker reaction time.

We are already connected with our customers today: Under "Digital Anticipation" in the Mercedes me app, customers purchasing new vehicles can gain exclusive insights into the production of their vehicles. For research and development as well as production, 360-degree networking means quick and transparent communication across all units. Digital tools are used for development and production, for example, production processes are visualised and optimized by "Virtual Reality" (VR) before a real production hall comes into existence. For example, the workstations and processes can be virtually tested and designed ergonomically.

,xPosition=0,yPosition=0.5)

,xPosition=0.5,yPosition=0)