October 13, 2023 – With the world’s first public crash test involving two fully electric vehicles, Mercedes-Benz is going above and beyond not only the legal requirements but also those of the ratings industry.

,xPosition=0,yPosition=0.5)

Real-life crash test

Mercedes-Benz AG

Mercedesstraße 120

70372 Stuttgart

Germany

Phone: +49 7 11 17-0

E-Mail: dialog@mercedes-benz.com

Please send queries about content on this website to any contact. You can address your concerns to us in English and your respective national language.

Represented by the Board of Management:

Ola Källenius, Chairman; Jörg Burzer, Mathias Geisen, Olaf Schick, Michael Schiebe, Britta Seeger, Oliver Thöne, Harald Wilhelm

Chairman of the Supervisory Board: Martin Brudermüller

Court of Registry: Stuttgart; commercial register no. 762873

VAT ID: DE 32 12 81 763

All information about our products can be found on your country-specific Mercedes-Benz product page.

,xPosition=0,yPosition=0.5)

Real-life crash test

October 13, 2023 – With the world’s first public crash test involving two fully electric vehicles, Mercedes-Benz is going above and beyond not only the legal requirements but also those of the ratings industry.

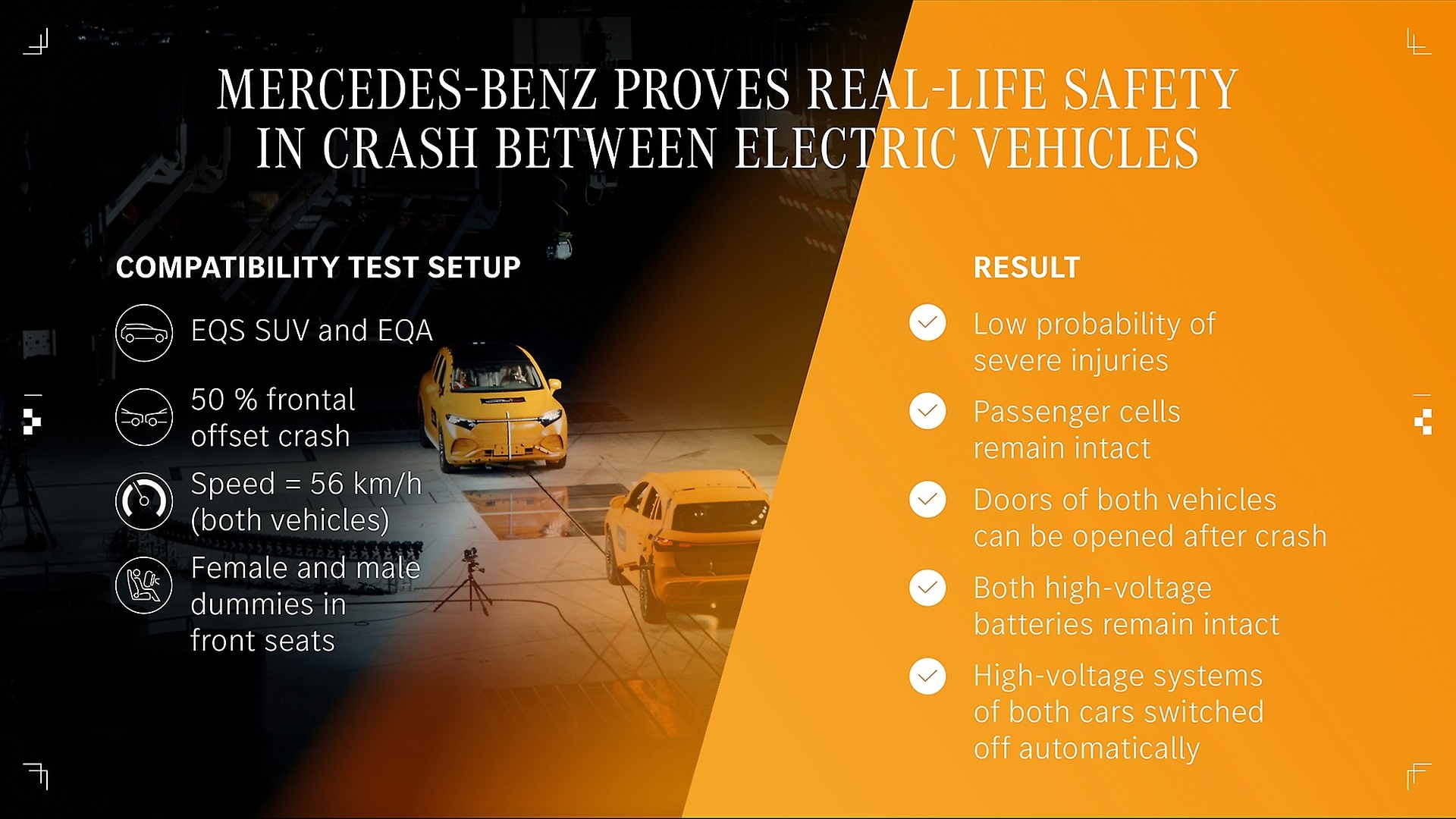

Euro NCAP stipulates a frontal impact test using a 1,400 kg trolley with an aluminium honeycomb barrier replicating the front of another vehicle. In accordance with the specifications, the test vehicle and the trolley collide with an overlap and at a speed of 50 km/h.

We use a third-party service to embed video content. This service may collect data about your activities. Please read through the details and agree to use the service to watch this video.

Mercedes-Benz, however, used two real vehicles, an EQA and an EQS SUV, which are significantly heavier at around 2.2 and three tonnes respectively. In addition, both models were faster, each going 56 km/h, which meant that the overall crash energy was considerably higher than required by law. The vehicles’ extensive deformation following the collision may seem alarming to the non-expert. For the Mercedes-Benz engineers, however, it shows that the vehicles were able to effectively absorb the energy of the collision by deforming. As a result, the passenger safety cell of both electric models remained intact and the doors could still be opened. In an emergency, this would make it possible for occupants to exit the vehicle on their own or for first responders and rescue personnel to reach them. The high-voltage system in the EQA and the EQS SUV switched off automatically during the collision.

The crash test at the Group’s Technology Centre for Vehicle Safety in Sindelfingen demonstrates Mercedes-Benz’s real-life safety philosophy: To make cars that hold up not only in defined crash test scenarios, but also in real-life accidents. The test scenario involving a speed of 56 km/h and 50 percent frontal overlap corresponds to a type of accident common on rural roads, for example during a failed overtaking manoeuvre. The speed selected for the test takes into account that, in a real-life accident, the drivers would still try to brake before the worst case of a collision.

Safety is part of Mercedes-Benz’s DNA and one of our core commitments to all road users. And to us, protecting human lives is not a question of drive system. The recent crash test involving two fully electric vehicles demonstrates this. It proves that all our vehicles have an equally high level of safety, no matter what technology drives them. We are working hard to achieve our vision of accident-free driving, which goes beyond the “Vision Zero” objectives set by the WHO and the United Nations Regional Commissions. We don’t just want zero traffic fatalities by 2050 and a halving in the number of traffic fatalities and serious injuries by 2030 compared to 2020. Our goal by 2050 is zero accidents involving a Mercedes-Benz vehicle.

Markus Schäfer, Member of the Board of Management of Mercedes-Benz Group AG, Chief Technology Officer

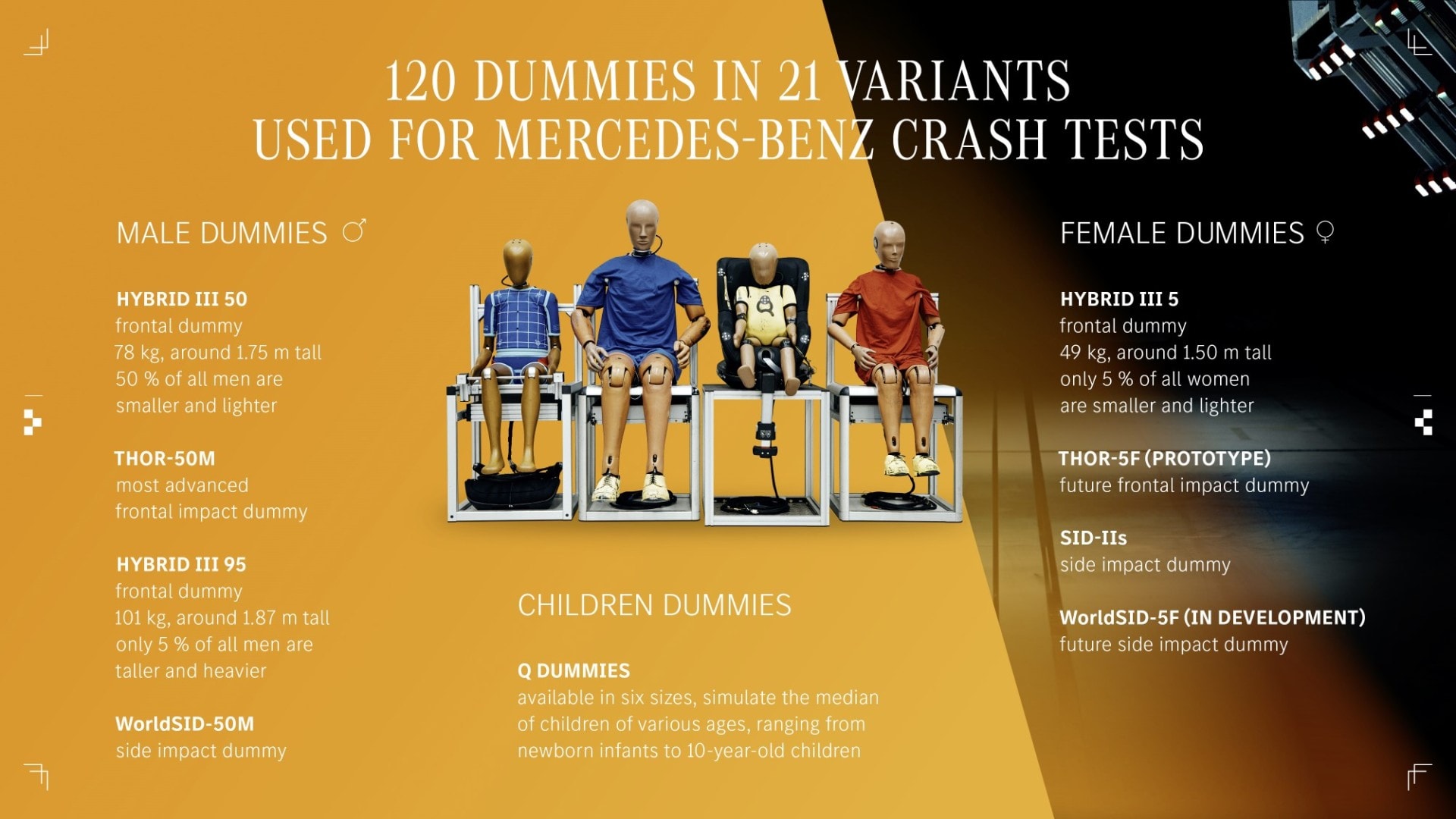

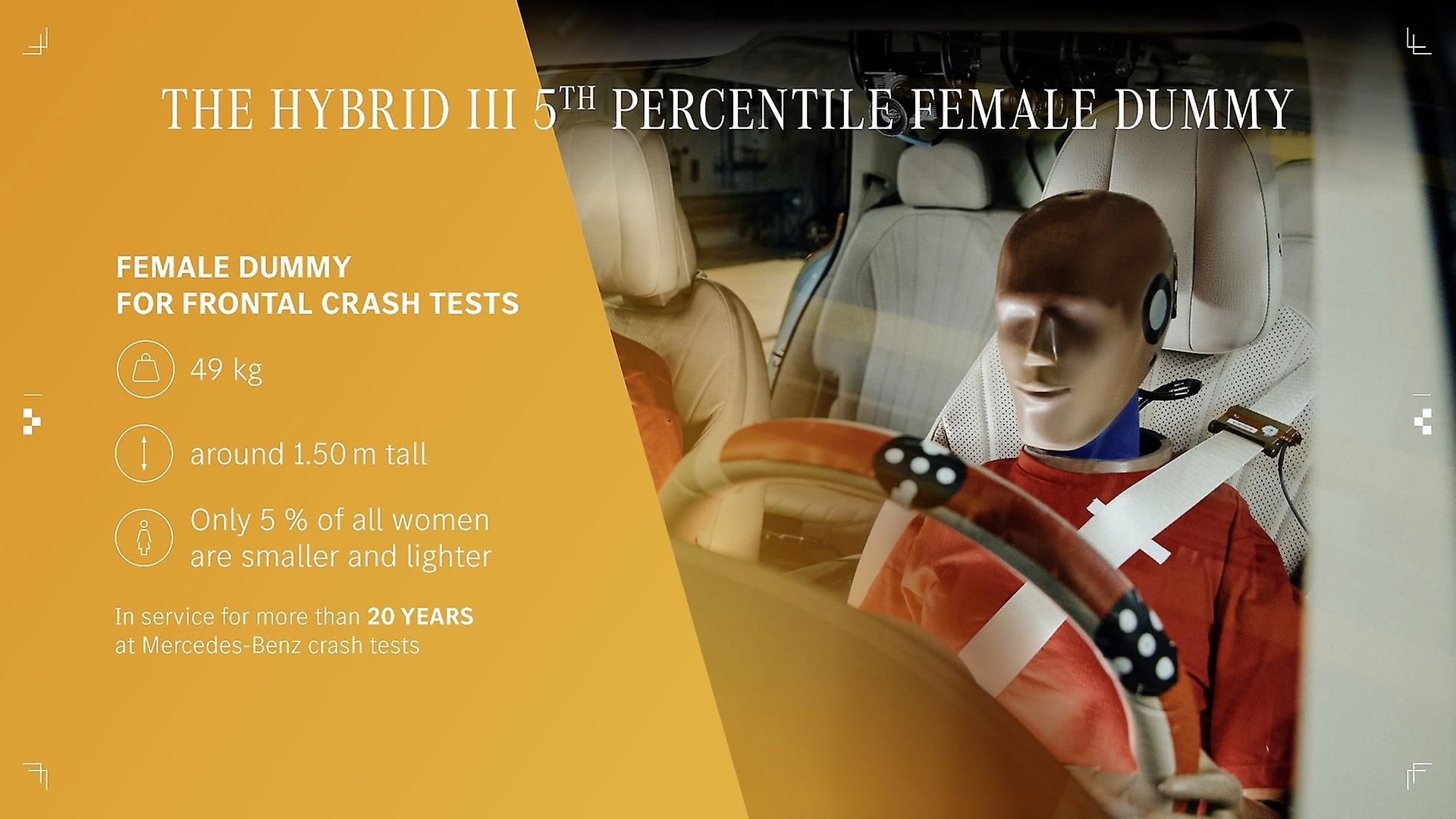

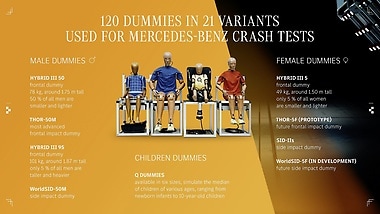

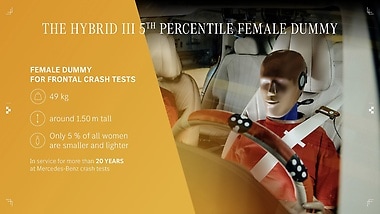

The EQA and the EQS SUV each carried two adult dummies – a total of three females and one male. Analysis of the up to 150 measuring points per dummy indicate a low risk of serious to fatal injury. This means that the defined crumple zones and advanced restraint systems in both vehicles offer very good protection potential for the occupants in a crash of this severity. All safety equipment, such as airbags and belt tensioners with belt force limiters, worked as intended. The crash test thus confirmed the results that the engineers had previously calculated in numerous computer simulations. Real-life vehicle testing always also serves as a final comparison with the simulations. Furthermore, the crash test clearly shows that compatibility (i.e. the interaction of the deformation structures of different vehicles involved in an accident) is part of the safety requirements for Mercedes-Benz cars.

This crash test involving two electric vehicles, which we have shared publicly for the first time in this way, underlines our commitment to building the world’s safest vehicles. The four female and male dummies complied with the biomechanical limits in this extremely severe crash. This demonstrates our expertise in electric vehicle safety.

Paul Dick, Head of Vehicle Safety at Mercedes-Benz AG

Mercedes-Benz has developed a multi-stage high-voltage protection concept for its electric vehicles. The system has eight key elements to ensure the safety of the battery and all components with a voltage above 60 volts. Examples include separate positive and negative wiring and a self-monitoring high-voltage system that automatically switches off in the event of a serious collision. In many cases, the company’s high internal safety standards exceed the legal requirements or those of consumer protection organisations. Mercedes-Benz has impressively demonstrated this once again with the latest crash test.