Mercedes-Benz is developing various forms of cell chemistry. Among other things, the company is working on lithium-ion cells with high-energy anodes based on silicon composites and innovative cobalt-free cathode chemistries, as well as on solid-state battery technology. The aim is to develop the best possible cells with

“Mercedes-Benz DNA” for high energy density, fast-charging capability and performance and to build up expertise for their industrialisation. Specifically, the energy density can be increased to up to 900 Wh/l through the use of new technologies such as high-silicon anodes or solid electrolytes. The only way to scale up production effectively is through comprehensive knowledge of cell chemistry and design. The knowledge gained flows into series production of battery cells at partner companies – for use in future generations of Mercedes-Benz batteries. The importance of mastering cell chemistry for the development of future products has been demonstrated by the VISION EQXX technology programme, for example. Thanks to a powerful battery with pioneering cell chemistry, this vehicle has set distance and efficiency records for electric vehicles on several journeys.

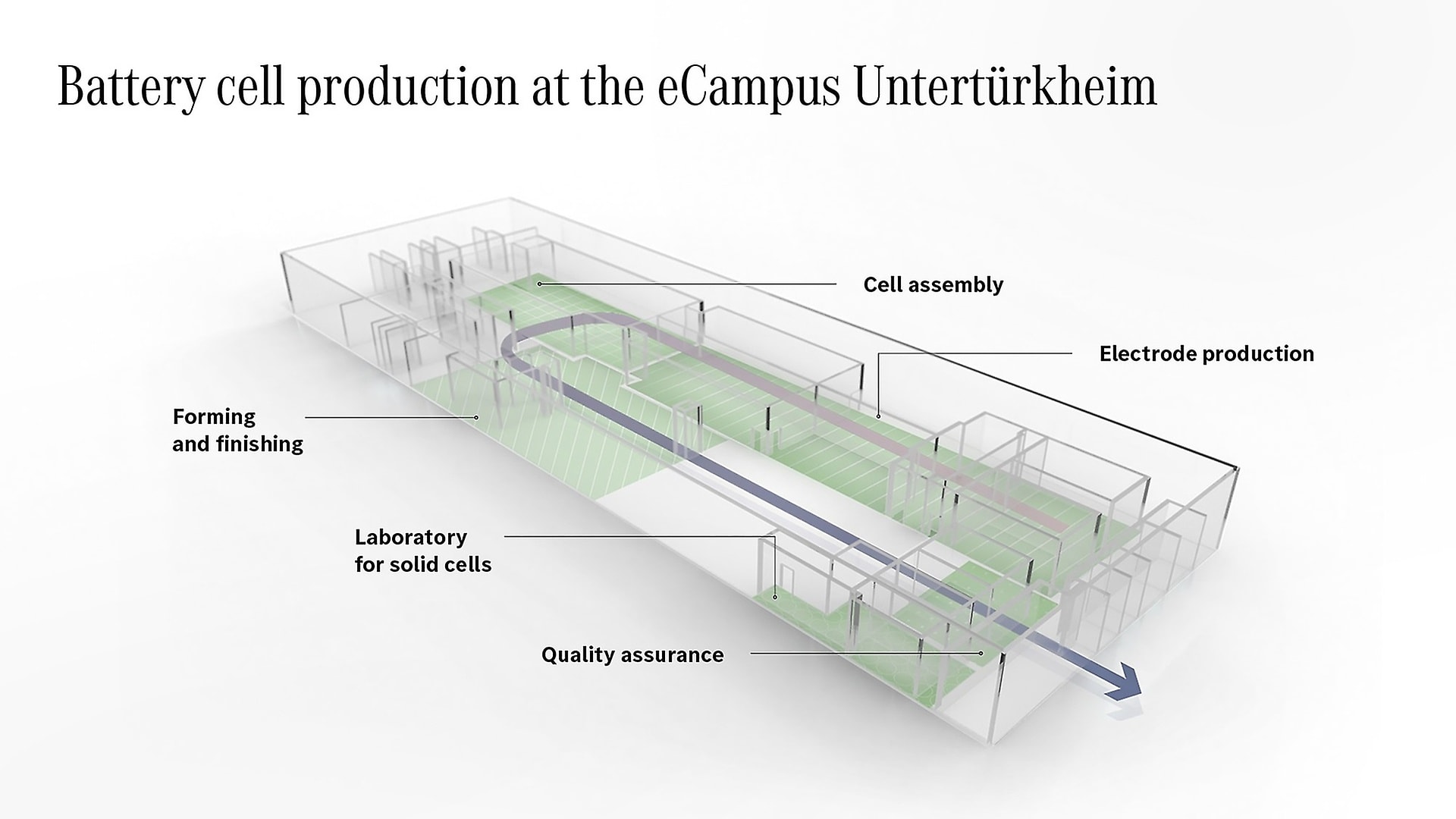

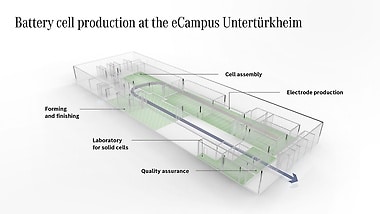

Operations at the new competence centre for battery technologies in the heart of the Stuttgart-Untertürkheim plant will start in two stages. The approximately 10,000-square-metre factory for the industrial production of battery cells has started operations after a construction period of around two years. State-of-the-art production facilities in the “Industrial Cell Lab” make it possible to manufacture and test battery cells with different chemistries on an industrial scale. Several tens of thousands of cells can be produced here every year for the development of future battery generations. The production process consists of a series of automated and manual steps. It covers all battery cell manufacturing steps from electrode production to cell assembly including electrolyte filling, forming with the first charging and discharging processes and finishing.

,xPosition=0,yPosition=0.5)

,xPosition=0.5,yPosition=0)

,xPosition=0.5,yPosition=0)