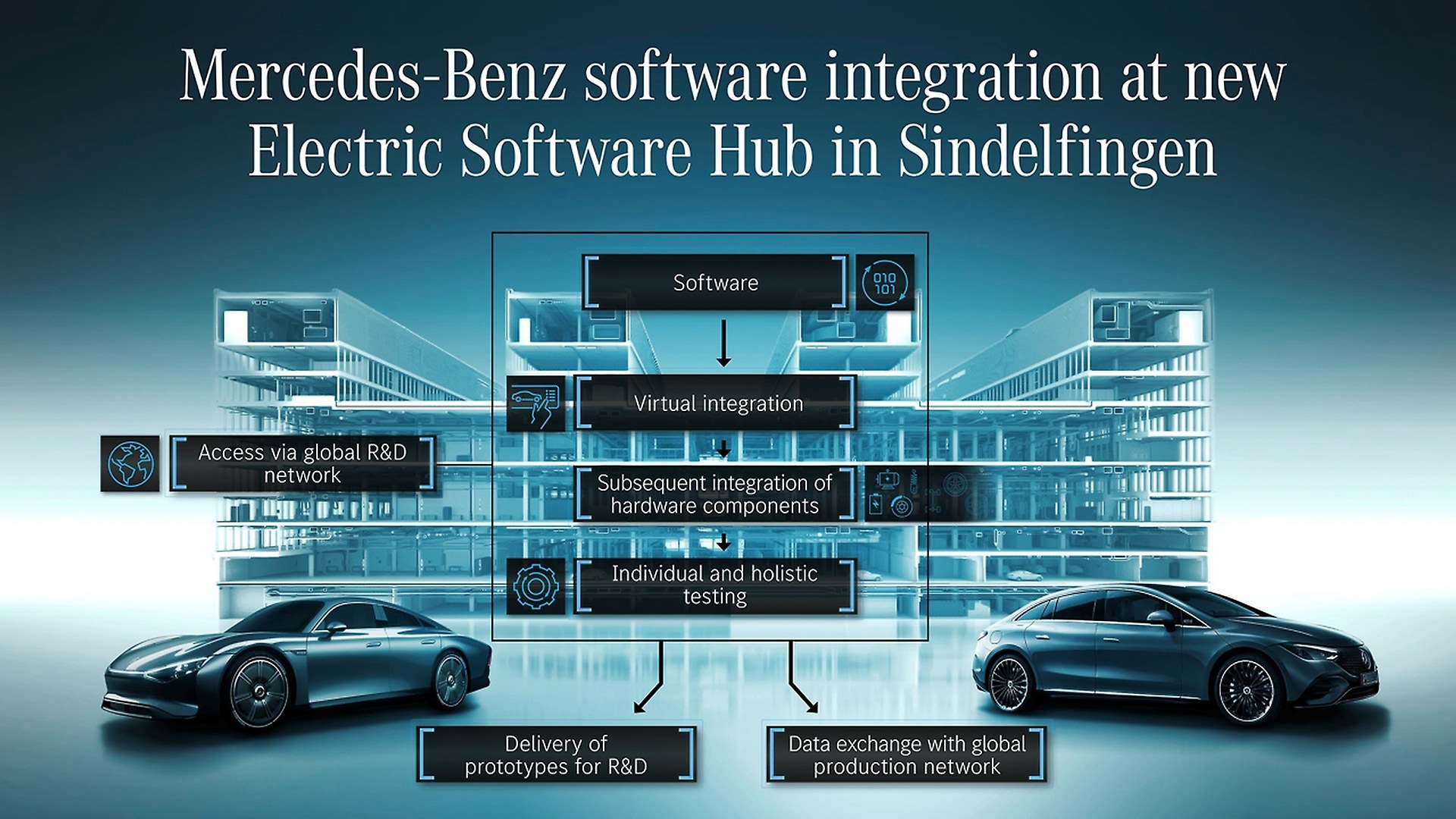

April 08, 2022 – Mercedes-Benz aims to be a leader in both electric driving and vehicle software. To accelerate this development, the company has invested more than 200 million euros in the Electric Software Hub at the Mercedes Technology Centre (MTC) in Sindelfingen. Numerous software, hardware, system integration and testing functions are brought together under one roof. With this step, Mercedes-Benz is intensifying its approach of cross-functional collaboration.

,xPosition=0,yPosition=0.5)

A software integration factory at the Sindelfingen site