A core element of our sustainable business strategy is Ambition 2039, with which we already set the course in 2019 for a holistic approach to climate protection and air pollution control. The ambition is to make our entire fleet of new vehicles net carbon-neutral along the entire value chain and over the vehicles' entire life cycle by 2039 – from development to the supplier network, in-house production, electrification of products to renewable energies in the use phase of electric vehicles and recycling of the vehicles to close the loop. The company aims to reduce CO₂-emissions per passenger car in the new vehicle fleet up to 50 percent along all stages of the value chain by the end of this decade compared to 2020 levels. To achieve this goal, the key levers include extensive use of recycled materials, usage of renewable energy in production, electrification of our vehicle fleet, and integration of renewable energy sources for charging.

Already a broad portfolio of all-electric vehicles

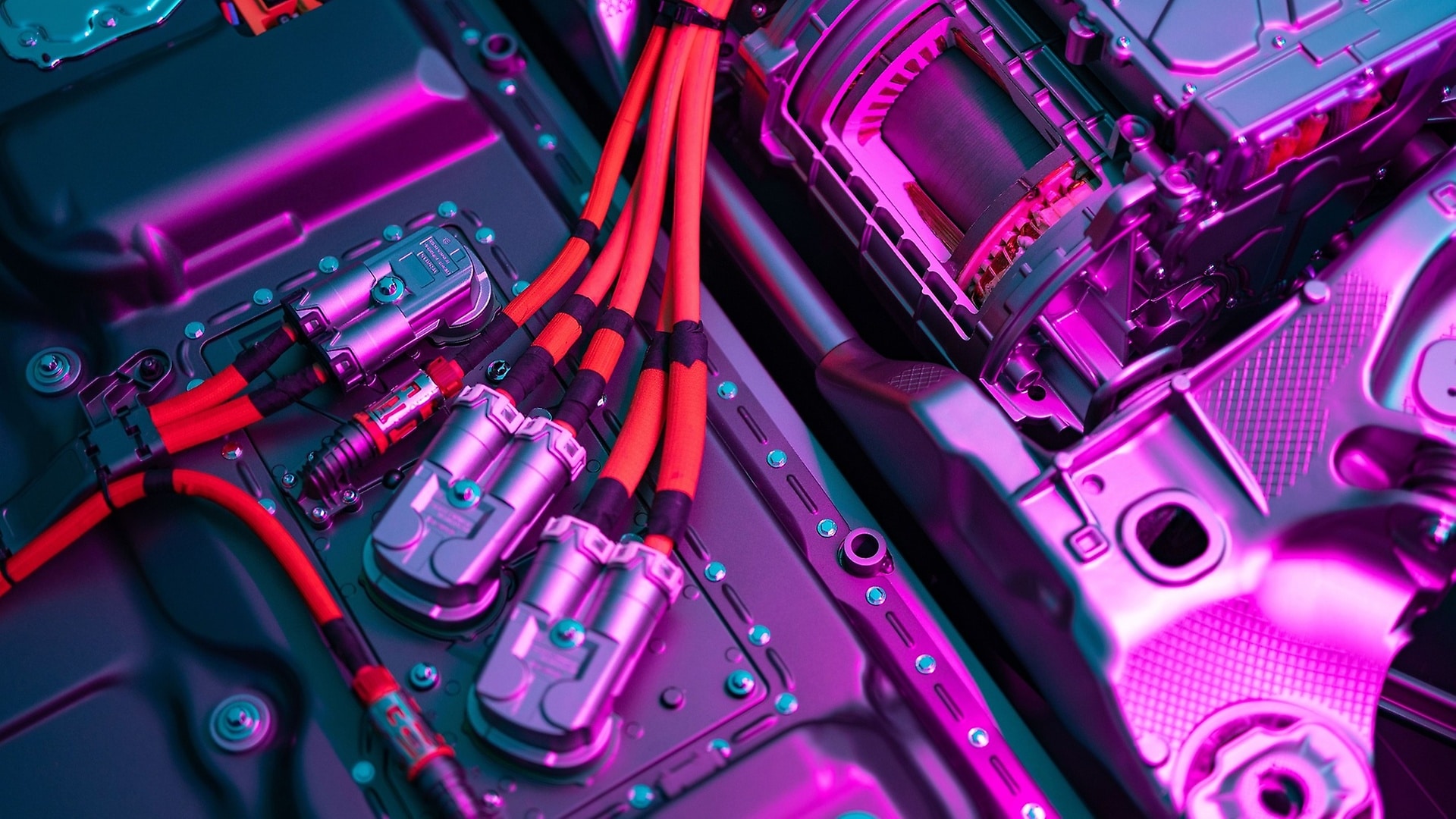

Mercedes-Benz is taking the necessary steps to go all electric. Customers and market conditions will set the pace of the transformation. We already offer a broad portfolio of battery-electric vehicles – from the compact EQA to the spacious EQS SUV. The ‚electric-first‘ platform MMA which will be launched in 2025, marks the next step into the electric future of Mercedes-Benz. The platforms MB.EA, AMG.EA and VAN.EA will follow. Thus, we will offer our customers a fully electric alternative for each model.

By 2026, we will have invested more than 60 billion euros on this transformation to prepare our production network to meet demand and be ready to capture the tipping point into an all-electric era.

Net carbon-neutral production since 2022

Mercedes-Benz’s own vehicle production locations achieved net carbon-neutrality in 2022, and the company plans to cover more than 70 percent of its energy needs through renewable energy by 2030 by rolling out solar and wind power at own sites as well as through further power purchase agreements. The ambition for all Mercedes-Benz production plants worldwide is to run 100 percent on renewable energy with zero CO₂ emissions by 2039.

By the end of 2023, solar plants with a capacity of more than 140 MWp (megawatt peak) are to go into operation. By 2025, we will invest a three-digit million sum in the installation of photovoltaic systems. In addition, investments in new power purchase agreements for wind turbines worth one billion euros are planned by the middle of the decade. The consumption of water in production is also expected to fall by 33 percent by 2030 compared to 2018.

"Factory56", one of the most modern automotive production facilities in the world, entered operation at the Mercedes-Benz Sindelfingen plant in 2020. It embodies the future of production at Mercedes-Benz and sets new standards for automotive manufacturing. In line with Ambition 2039, Factory 56 is net carbon-neutral and produces with a significantly reduced energy requirement. This is made possible, among other things, by an innovative energy concept with a photovoltaic system, a DC grid and energy storage systems based on recycled vehicle batteries.

Extraordinary green power concept

Mercedes-Benz is currently implementing a green power concept in Germany with the energy supplier Enovos and the Norwegian energy producer Statkraft. Since 2022, we have been purchasing electricity that comes exclusively from renewable sources. A green power supply contract ensures the purchase of electricity from renewable energies at all times.

Together for climate protection

» Key criterion for supplier selection: With its Ambition 2039, Mercedes-Benz is pursuing the goal of offering net carbon-neutrality along the entire value chain in our fleet of new vehicles in less than 20 years. However, the transformation to electric mobility increases the energy demand in the upstream supply chain. A holistic approach on the path to all-electric mobility therefore also includes our suppliers. Together with our partners in the supply chain, we want to implement effective climate protection measures. Our goal is to prevent, minimise or, as far as possible, eliminate potential environmental impacts along our supply chain.

In doing so, we focus on materials and components that are particularly CO₂-intensive in production and processing. The focus components include aluminium, steel, and battery cells. We have already reached some important milestones here: we have made net carbon-neutral cell production a central requirement for all our battery cell partners. This allows us to reduce emissions in battery production by around 30 per cent. In addition, Mercedes-Benz Cars and Vans are engaged in ongoing negotiations with other players in the supply chain – including electrode producers, refineries and mines. The EQS was our first vehicle with cells produced in a net carbon-neutral way. The net carbon-neutral production at the partners was additionally verified and confirmed by the expert and testing organisations SGS and DEKRA.

» Audited mining of cobalt and lithium: We rely on sustainable supply chains for our electric fleet and think about the responsible use of raw materials right from the start. Our goal is to ensure that our products contain only materials, raw and otherwise, that have been mined and produced without violating human rights and environmental standards. We therefore require our direct suppliers to comply with our Responsible Sourcing Standards (RSS) and to carry them into their upstream value chains as well as to monitor their compliance. The RSS apply worldwide and represent our code of conduct for the supply chain and include binding minimum requirements for suppliers. Mining audit is another important tool to carry out due diligence in raw material supply chains and to address environmental and human rights risks that depend on the on-site management of the mine. In addition, Mercedes-Benz makes the "Standard for Responsible Mining" of the "Initiative for Responsible Mining Assurance" (IRMA) a key criterion for supplier decisions and contracts in raw material supply chains and will only work with suppliers who agree to these requirements. As early as 2018, we commissioned RCS Global to create transparency along the complex cobalt supply chains of our battery cells and to check them against the OECD due diligence guidelines. In view of increasing requirements for due diligence and transparency in the supply chains of battery cells, we are not only continuing to implement audit and transparency measures in cooperation with RCS Global, but are also extending them to the raw materials lithium, nickel, graphite, copper and manganese in addition to cobalt. In addition, the scope of human rights due diligence has been extended to environmental aspects such as biodiversity, water protection, water protection, hazardous substances and energy management.

For years, we have also been investing in resource-efficient technologies and manufacturing processes for batteries and are working to further reduce the use of critical materials. The cobalt content in the cathodes of the EQS battery cells, for example, is less than ten per cent and has been significantly reduced compared to the previous battery generation. In the future, we want to use post-lithium-ion technologies with new material compositions to completely eliminate materials such as cobalt. The further optimisation of recyclability and its implementation is also part of our holistic battery strategy.

More information on the handling of risk raw materials.

In addition, we address CO₂ emissions in our supply chain via the so-called "Ambition Letter". For new contracts, we only accept suppliers who have confirmed in writing that they will supply us with CO₂-neutral products from 2039 at the latest - and thus meet our climate targets. This means that only when the Ambition Letter has been signed suppliers do have a chance of being selected for the contract. In this way, we create a good basis for initiating actual reductions with our direct suppliers and in the supply chain. In 2023 suppliers representing 84 percent of Mercedes-Benz's annual purchasing volume have already signed an Ambition Letter, agreeing to supply us only with net carbon neutral production materials in the future.

Together with our suppliers, we are also working on a green, net-carbon-free steel supply chain. Before the end of this decade, we aim to purchase more than 200,000 metric tons of CO₂-reduced steel annually from our European suppliers Salzgitter, thyssenkrupp Steel, voestalpine, Arvedi, SSAB and H2 Green Steel (H2GS) for our press shops. We are already sourcing CO₂-reduced flat steel from Salzgitter Flachstahl GmbH. This is made from 100 percent scrap in an electric arc furnace. We also already source CO₂-reduced steel from our Italian steel partner Arvedi. In 2022, we became the first passenger car manufacturer to receive steel from SSAB's hydrogen-based direct reduction. We intend to use virtually CO₂-free steel from industrial production from 2026. We have agreed with H2GS on an annual purchase of around 50,000 tons of virtually CO₂-free steel per year, which is to be used in various production models. The strategic partner plans to start production in 2025. In September 2023, we also signed a supply agreement with Steel Dynamics, Inc. (SDI) for more than 50,000 metric tons of CO₂-reduced steel annually for our production plant in Tuscaloosa, Alabama. The steel supplied by SDI is produced in an electric arc furnace (EAF) that runs on 100 percent green electricity and has a scrap content of at least 70 percent.

Aluminium, together with steel, is proportionally the most widely used material in many vehicles and is gaining in importance in electric vehicles. Therefore, we are also pursuing a clear roadmap of a carbon reduced aluminium supply chain – and have already reached important milestones.

In Europe, at least one third of the aluminium we use in our upcoming electric model generation is produced with renewable energy. Together with the Norwegian aluminium producer Hydro, we are going one step further and developing a technology roadmap to decarbonise the aluminium supply chain by 2030. Hydro is already supplying our foundry in Stuttgart Mettingen with CO₂-reduced aluminium. The strategic cooperation takes the collaboration to a new level: The first material from Norway with a CO₂ reduction of almost 70 percent compared to the European average and a scrap share of 25 percent has already been tested and has been used since 2023 in the series production of the EQS and EQE, among others. By 2030, we want to reduce the aluminium footprint with Hydro by more than 90 per cent with the help of new innovations. However, we are not only concerned with further reducing emissions. Another goal is to reduce the use of primary resources by increasing the use of secondary materials from post-consumer scrap.

» Circular economy in battery systems: As part of our holistic approach, we also think about the circular economy when developing battery technology. In March 2023, we laid the symbolic cornerstone for a battery recycling factory based on hydrometallurgy at the Kuppenheim site. In the future, it will cover all steps from dismantling at module level, through crushing and drying, to processing the material streams to battery quality. The process design should enable recovery rates of more than 96 per cent. Mercedes-Benz is also cooperating with high-tech partners for battery recycling in China and the USA.

More information about the battery circular economy,

» Extensive use of recycled materials: We work intensively to close material loops and increase the proportion of recycled materials to conserve primary resources, avoid waste and thus also reduce CO₂ emissions. In Development we follow the "Design for Environment" approach: As early as the design stage of our vehicles, we reconsider the composition of all materials used and examine possibilities for more sustainable alternatives. By 2030, we want to increase the share of recycled materials in our new vehicle fleet to an average of 40 per cent. In addition to steel and aluminium, innovative recyclates are already in use. For example, the cable ducts of the EQS and EQE are made of the plastic substitute UBQ™, which is produced from upcycled household waste. The floor coverings in the EQS and EQE SUV contain a nylon yarn derived from recyclable materials such as fishing nets and carpets. For the EQE, EQE SUV and the S-Class, bow door handles made from chemically recycled materials are available. In their production, fossil raw materials are replaced by biomethane and pyrolysis oil from recycled used tyres. In the vehicle interior, in addition to a high-quality artificial leather and a microfibre fleece, we offer various fabrics made up to 100 per cent from recycled PET bottles. In the basic seat of the new E-Class, undyed alpaca wool combined with a recycled material is used for the upholstery. In the foam of the seats, certified recycled raw materials are used for the first time according to the "mass balance approach", and their properties do not differ from those of raw materials produced from crude oil. In this way, the need for fossil resources can be reduced while maintaining product quality. Furthermore, Mercedes-Benz has entered first components from chemical recycling into series production. Since 2022 the EQE and S-Class are the first series-production models which are available with bow door handles manufactured using a combination of biomethane and pyrolysis oil made from scrap tyres, instead of raw fossil resources. The S-Class also comes with a crash absorber based on this combination of raw materials. Looking to the future, the aim is to progressively increase the use of this more sustainable recycled material, and also to use chemical recycling in combination with the biomass balance approach for further plastic vehicle parts.

A sustainable mobility experience

Green Charging: Around 50 per cent of the CO₂ footprint of a battery-electric vehicle is produced during the use phase with the current EU energy mix, owing to charging processes that emit CO₂.

With Mercedes me Charge, we have been enabling our customers to charge with green electricity¹ at public charging points in Europe, the USA and Canada since 2021. Mercedes me Charge is integrated into one of the world's largest and steadily growing charging networks with more than 1.6 million charging points – around 500,000 of which are in Europe. In addition, Mercedes-Benz is building its own global high-power charging network in North America, Europe, China, and other core markets with around 2,000 locations and over 10,000 charging points by the end of decade. In line with its sustainable business strategy “Ambition 2039”, Mercedes-Benz enables Green Charging for its customers within its own charging network. This is ensured preferably via green electricity supply contracts wherever possible or by using renewable energy certificates from an accredited supplier.

The central aim of the brand is to offer customers more than just an unrivalled electric driving experience. With our EQ models, you are immersed in a completely new Mercedes world that thrills not only the mind but also the heart with its technical possibilities and sustainable innovations. This exciting, unrivalled experience goes well beyond the product itself. With Green Charging, we actively contribute to reducing our carbon footprint and are thereby leading the way to the net carbon-neutral mobility of the future with our Ambition 2039.

» Mercedes me Eco Coach: To give customers special support when switching over to the age of electric mobility, we have developed an intelligent, digital personal trainer: the Mercedes me Eco Coach. Customers who follow the recommendations and hints in the app not only get to know their alternative-drive car better – they also improve their driving style and thereby protect the environment.

¹Green Charging ensures that the appropriate amounts of green energy are fed into the grid after the charging process. Guarantees of origin or Renewable Energy Certificates are used for this purpose, which verifiably certify the origin of the energy and serve as a kind of birth certificate for electricity from renewable energies. The green electricity is defined by the EKOenergy eco-label, which is provided by certified energy production plants.

This article was last updated in April 2024.