Planners and operators at all locations identify projects and implement the measures throughout Europe. In practice, the construction of the new “Factory 56”at the Mercedes-Benz Sindelfingen Plant is a showcase project. That is because the new factory will already be carbon-neutral when it starts operation and will be supplied completely with green electricity. In addition, a photovoltaic system on the roof will provide self-produced electricity for the building.

Other Mercedes-Benz plants are already realizing high-efficiency energy concepts as well, such as Rastatt in the new body shell building. It uses a dual-purpose heat pump for heating and cooling as well as optimized ventilation systems. The effect: zero percent fossil fuels for heating the building.

Minor and major measures – everything helps to achieve the goal

Back on the energy and environment path, it becomes clear that sustainable production is an interplay of many major and minor elements. Heiko Engel cites the example of using ammonia in one of the vapor-compression refrigeration systems, which we are walking past just then. "It is one of the best natural refrigerants, because it does not harm the ozone layer," he explains. A quick look at the website tells us that the energy-efficient cooling system running on ammonia also saves 1,300 metric tons in CO₂ emissions. And even losses can still be used, for example, for generating compressed air. The powerful compressors actually are not very effective at 20 percent efficiency. The energy team switched the compressors to high-temperature cooling, which increases the coolant temperature to up to 78 degrees Celsius. Buildings such as the Customer Center, for example, are heated with this usable ‘waste heat”.

Environmental protection in practice

Sustainable production also comprises the sensible use of water, wastewater and solid waste. The environmental protection team in Rastatt headed by Verena Mecke and Heiko Kärst has also compiled numerous practical examples related to these topics for the environment info path. "My wish is to get colleagues and visitors enthusiastic about the protection of the environment," says Verena Mecke. The head of Occupational Safety and Environmental Protection Management is preaching to the choir in this regard, because more and more colleagues and customers are interested in sustainability issues. They benefit from the interplay of guided factory tour and the website and in addition get plenty of tips on the mindful use of natural resources.

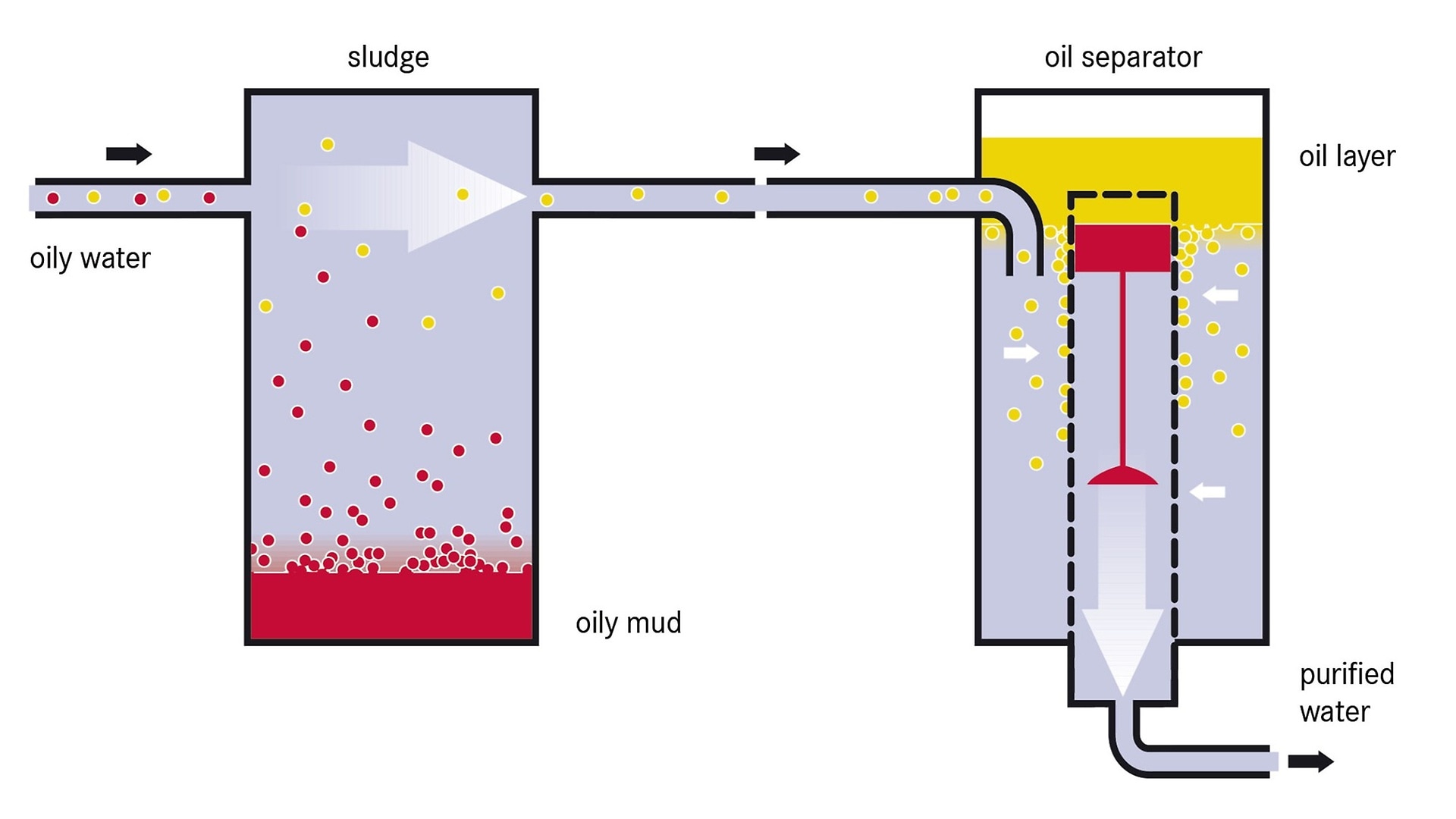

For example, the use of water. "We clarify this is the title of the blue stele next to the car wash. That is were a lot of wastewater is generated, which may contain oil and pollutants. "This water has to be pretreated before we put it back into the water cycle”, explains environmental expert Heiko Kärst. We can't see this process, but it’s shown to us in graphic on the website: The heavy components of the wastewater sink to the bottom of a large tank, the light ones float on top. Assisted by a separator, they slowly fuse into a compact sludge, which is disposed on a regular basis.

,xPosition=0,yPosition=0.5)

,xPosition=0.5,yPosition=0)

,xPosition=0.5,yPosition=0)

,xPosition=0.5,yPosition=0)