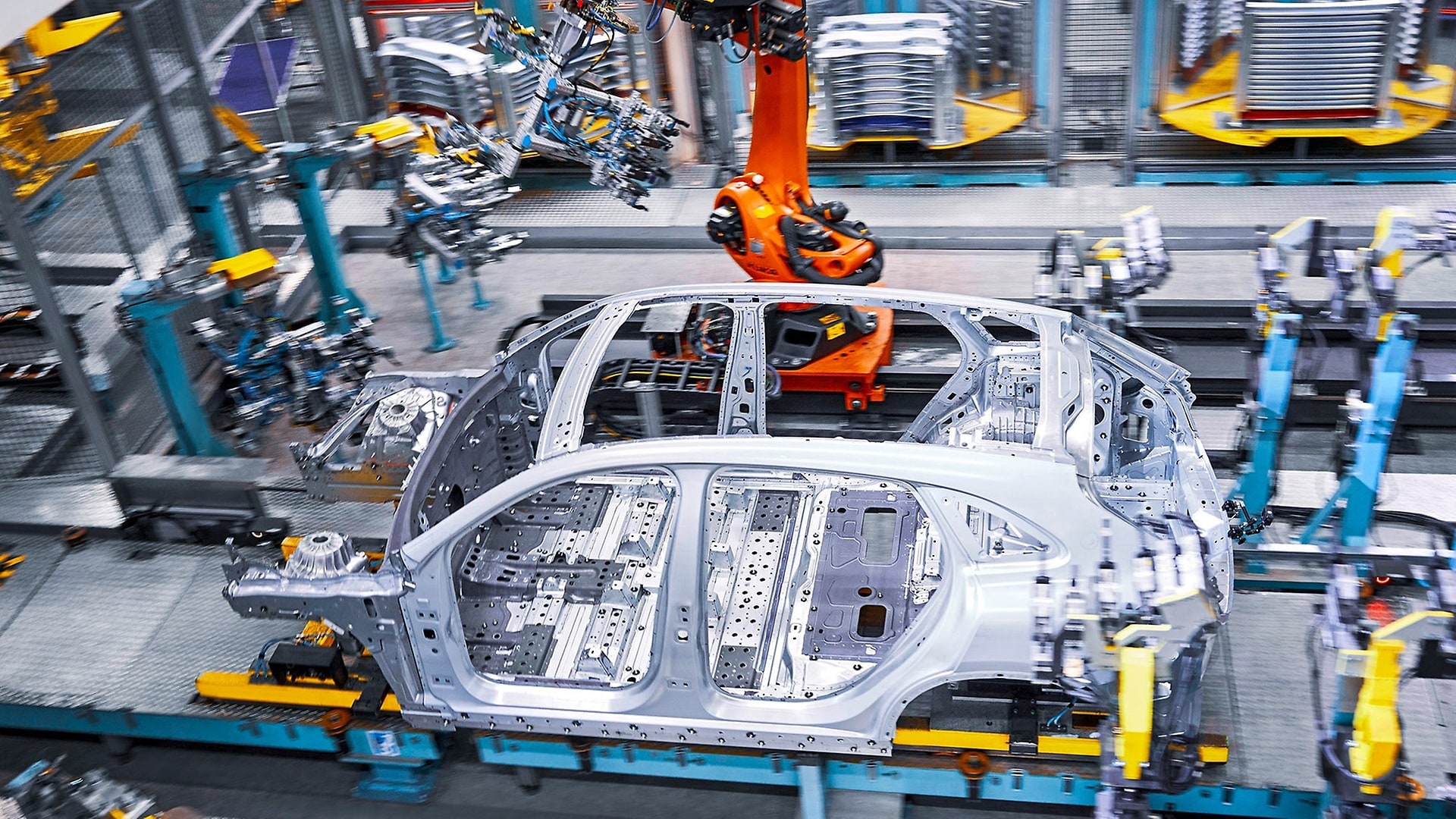

As part of the Mercedes-Benz Business Plan, the company invested more than two billion euros in its European assembly plants. With their manufacturing expertise and consistent digitalization, these locations make a key contribution towards the successful implementation of the global production strategy. Following the successful ramp-up of the electric CLA, the first model based on the Mercedes Modular Architecture (MMA), at the Rastatt plant, the company is now continuing its product launch campaign with models in the Core and Top-End segments.

In parallel with the electric Mercedes-Benz GLC in Bremen and the electric C-Class in Kecskemét, the Sindelfingen plant is preparing for the production of the new electric Mercedes-AMG models, which are already in their testing phase. Bremen and Sindelfingen will continue to act as lead plants for the models in the Core and Top-End segments. With this, Mercedes-Benz reaffirms Germany's key role as an industrial location within the global production strategy.

Production costs will decrease by ten percent between 2024 and 2027. This will be achieved through a number of measures, including greater efficiency in production and logistics thanks to digitalization, as well as the use of artificial intelligence and digital twins and the increased use of renewable energies. In addition, the low-cost country share will be increased from 15 to 30 percent by 2027.

,xPosition=0,yPosition=0.5)

,xPosition=0.5,yPosition=0)

,xPosition=0.5,yPosition=0)

,xPosition=0.5,yPosition=0)