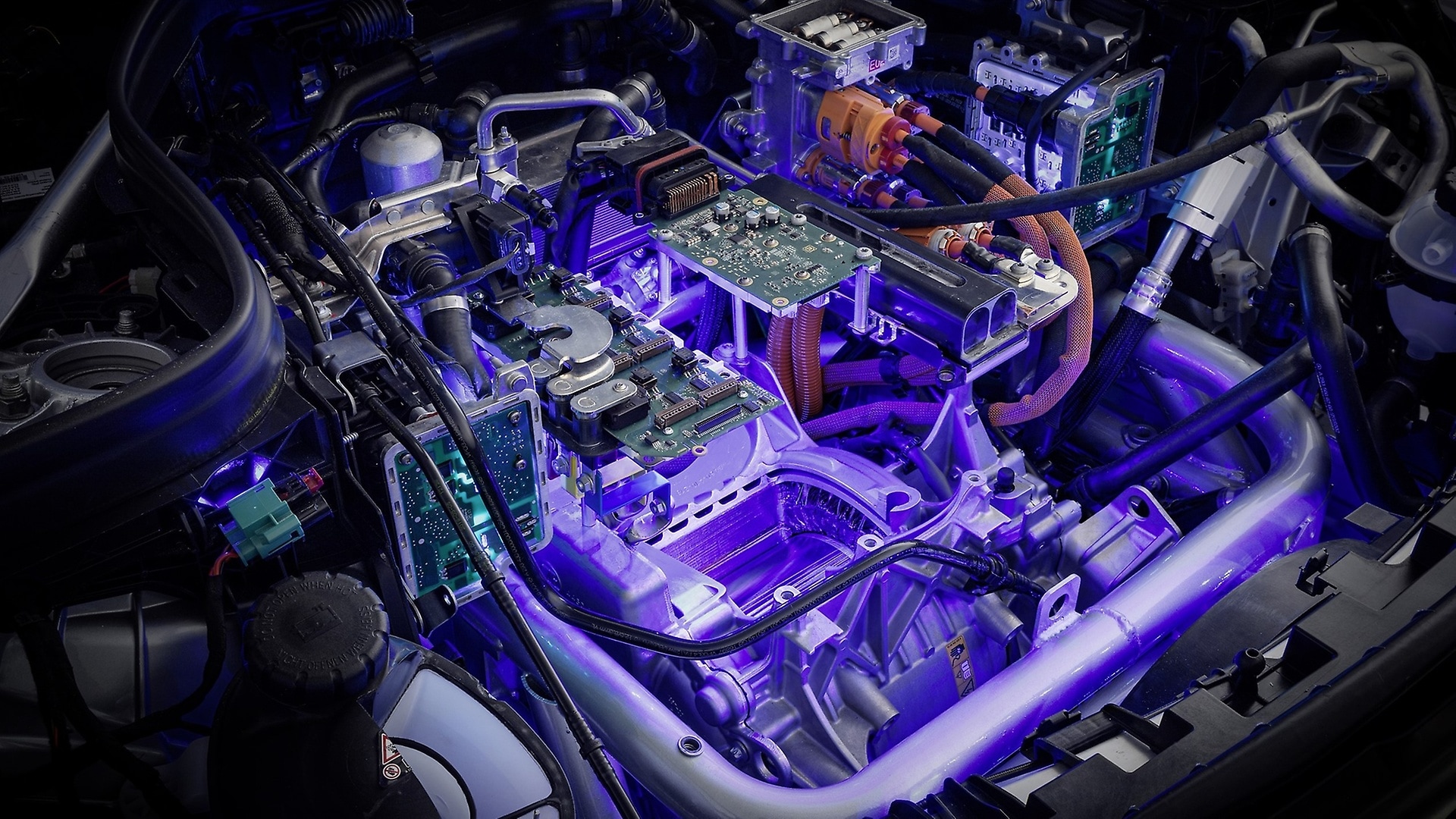

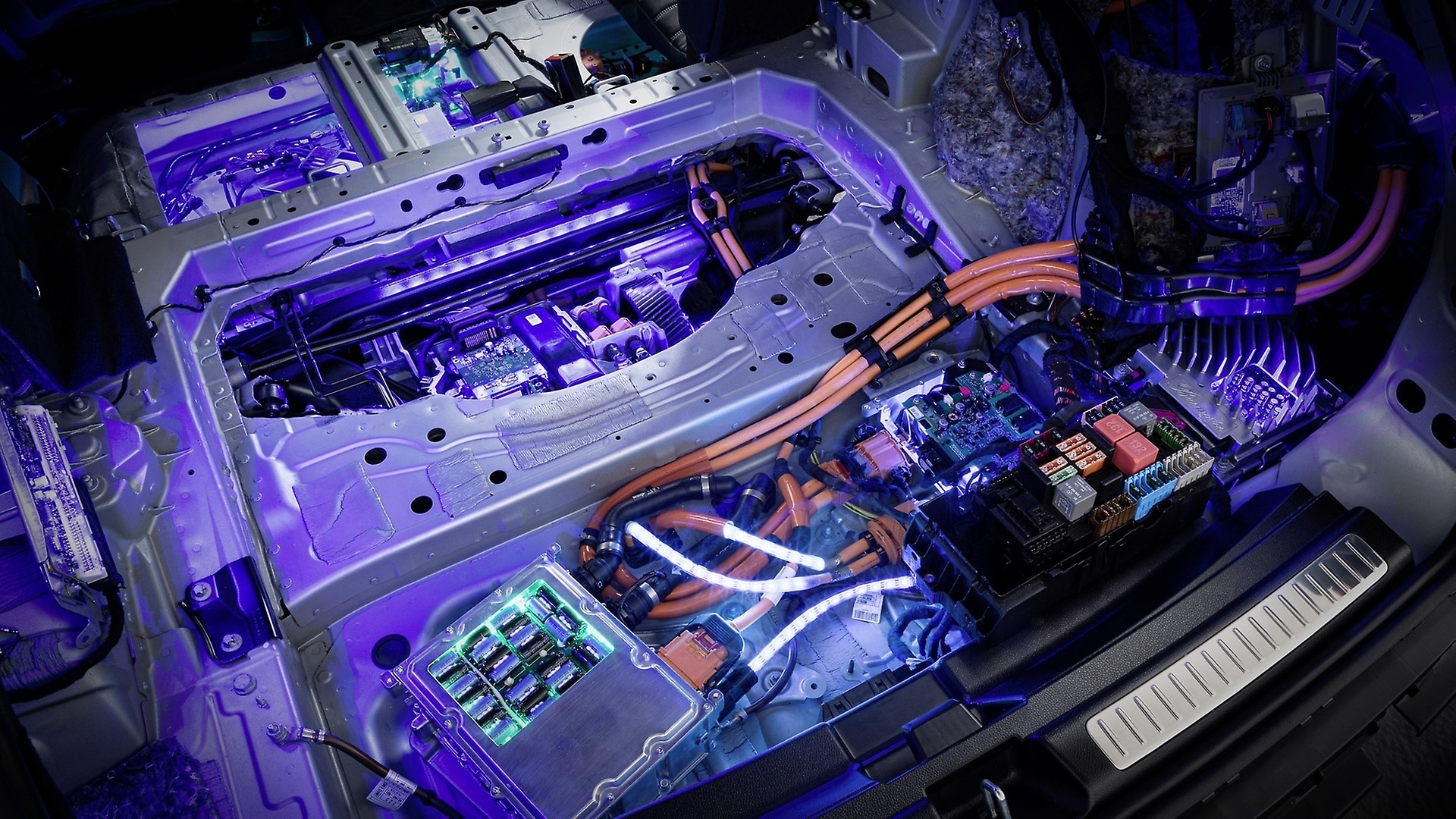

October 21, 2020 – What does the technology of a modern electric car look like? To answer that question, Mercedes-Benz trainees prepared an EQC 400 4MATIC in a way that rendered the inner components of the car visible. The EQC's left half is still in its original state while the right half was fitted with cuts in the vehicle body and floor. This offers a view of the otherwise concealed technology.

,xPosition=0,yPosition=0.5)

Transparent electromobility