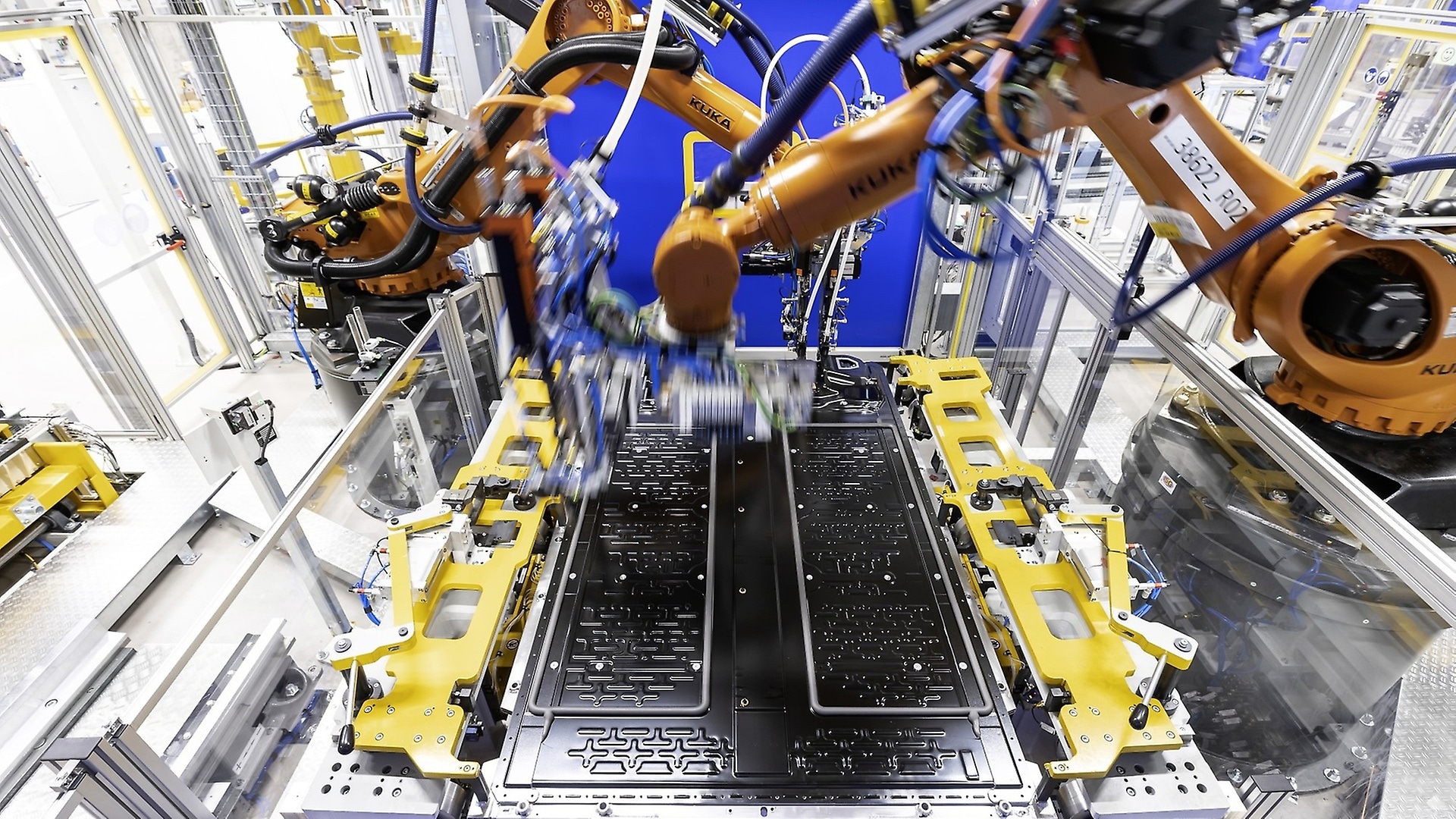

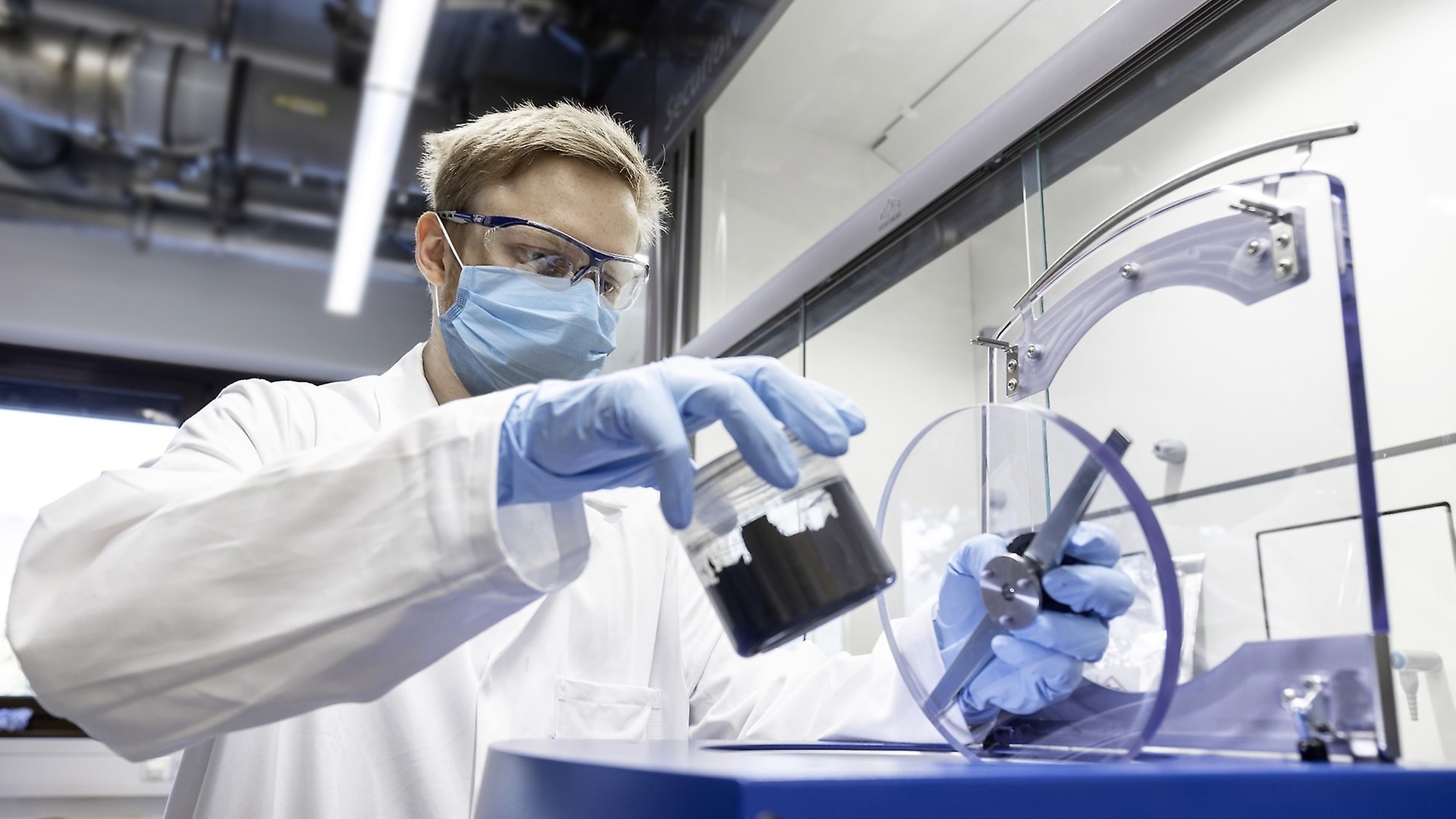

With the bundling and extension of its battery activities at the Mercedes-Benz Drive Systems Campus at the Untertürkheim site (Germany) the company strengthens its expertise in the field of e-mobility. Research and development activities are already anchored at the location, such as the e-technology center and cell technology center, where, among other things, prototypes for the electric drive system are built and cell technologies are researched and tested. The findings from our international research hubs will be centralized at this location.

In order to deepen its competence as a center for battery technology, a new factory for the small-series production of future lithium-ion battery cells is being planned, starting its operations in 2023. The sustainability factor, transparent cell development through to recyclability, plays a major role in this. The focus on in-house know-how and high vertical integration is key for a leading role in electric vehicles. Mercedes-Benz plans to invest a three-digit million amount in the transformation of the site.

,xPosition=0,yPosition=0.5)

,xPosition=0.5,yPosition=0)

,xPosition=0.5,yPosition=0)