The battery systems manufactured in the new battery factory, are used among others for the current Mercedes-Benz C-Class, E-Class, S-Class as well as for the Mercedes-Benz GLC and GLC Coupé. The high variety of product variants of the local market require very flexible and efficient production and facility concepts. Central assembly stations were set up in the same way as in the battery factory in Kamenz and were further developed for site-specific requirements. In this way, all battery types can be manufactured in the new line for all current and future plug-in hybrids.

The battery factory in Bangkok meets the high Mercedes-Benz standards in terms of ergonomics, industrial safety and digitalization. For example, a new benchmark has been implemented for process assurance: The excellent product quality is generated by a quality assurance system that monitors all production processes online along the value creation. In addition the plant has its own assessment and testing centre.

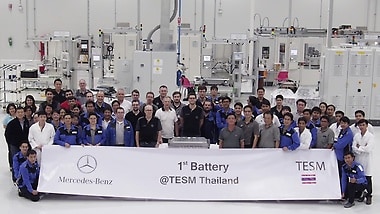

In order to prepare employees in the best possible way for their new, demanding tasks, they were intensively trained. Mercedes-Benz Cars benefits from the experience gained from its international production network.

,xPosition=0,yPosition=0.5)

,xPosition=0.5,yPosition=0)