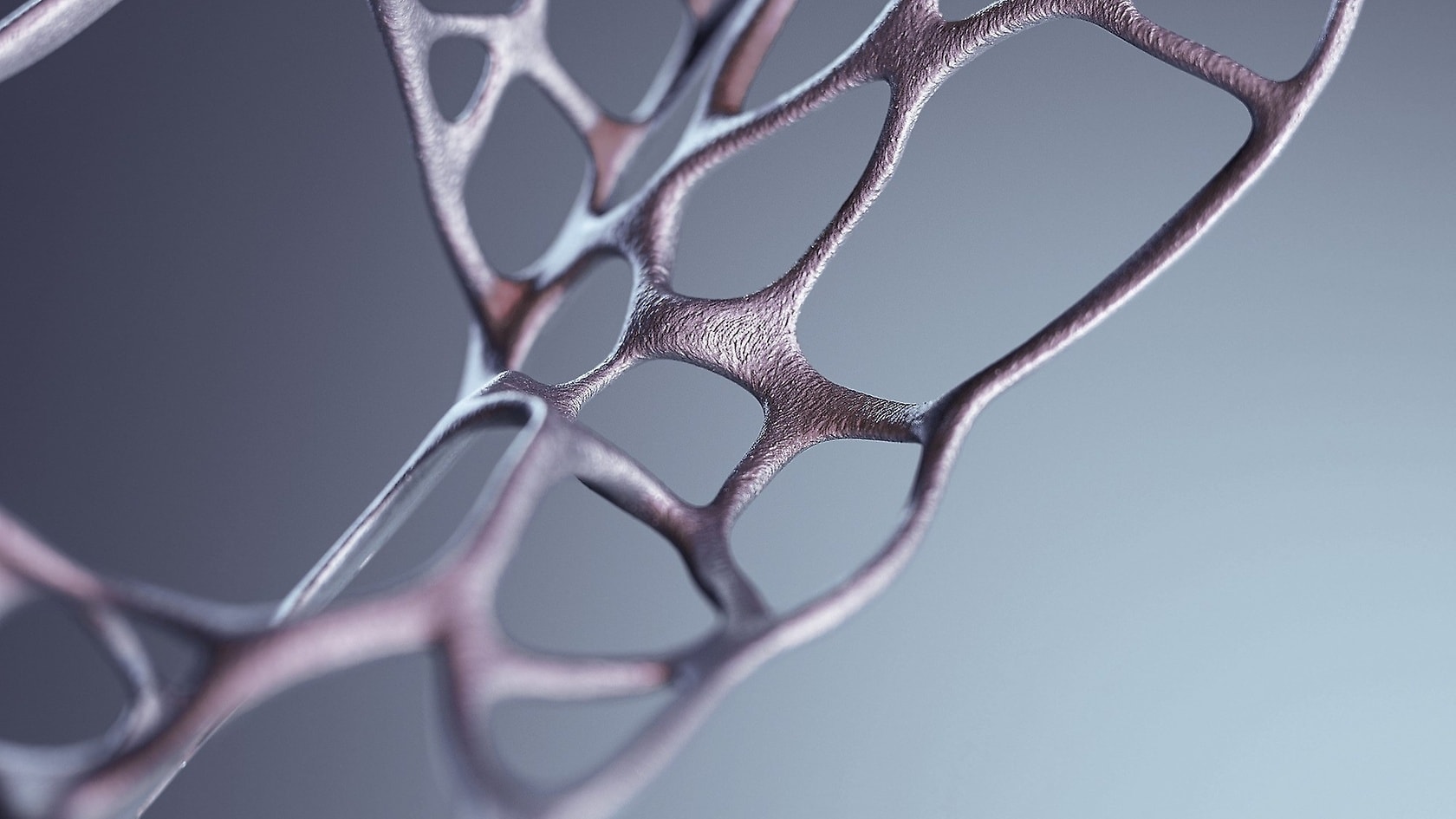

March 05, 2024 – When it comes to lightweight construction, nature is still the best role model: from boxfishes to the Arctic tern – many animals have evolved optimal body shapes and other capabilities that enable them to travel their migratory routes with minimal expenditure of energy. Maximum efficiency was also the guiding principle behind the technology programme that produced the VISION EQXX – which is why parts of the chassis structure are based on natural shapes and bionic design principles. That means material is used only where load paths are absolutely necessary. That is why the bionic elements have constantly varying wall thicknesses and openings reminiscent of a skeleton.

Inspired by nature