Mercedes-Benz is not only committed to socially and environmentally compatible raw material extraction, but in addition to risk assessment in accordance with international standards, we also attach great importance to active participation in industry initiatives. They help to make complex supply chains more responsible through joint measures - including the lithium supply chains.

To achieve this, Mercedes-Benz Procurement is making the industry-wide recognized "Standard for Responsible Mining" of the "Initiative for Responsible Mining Assurance" (IRMA) one of the key criteria for supplier decisions and supplier contracts. With the company’s contracts, partners commit to using only lithium in their own supply chain that comes from mines audited in accordance with the IRMA mining standard. The most important criteria of this standard include both human rights aspects and the environmentally friendly mining of raw materials. The standard also takes into consideration further social and societal aspects that are related to the consequences of industrial mining.

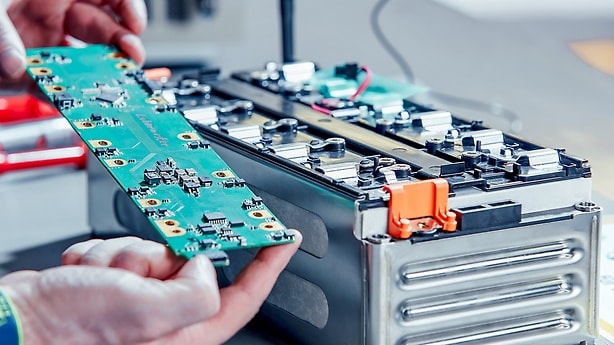

Our focus, however, is not only on the mines and raw material extraction. We are committed to ensuring that human rights are respected and that the raw material is processed in an environmentally friendly manner throughout all stages of the value chain. Since 2022, we have therefore been working together with the audit and consulting company RCS Global to create transparency across the entire lithium supply chains of our battery cells and have them audited across all stages on a risk-based basis in accordance with OECD due diligence guidelines. This effort is based on initial progress in the cobalt supply chains and has been extended to other battery raw materials, including nickel, graphite, manganese and copper in addition to cobalt and lithium. You can find more information here.