The battery is the central component of an electric vehicle – and also the one with the highest carbon footprint. Mercedes Benz is therefore pursuing a holistic, multi-stage transformation approach to decarbonising the battery cell supply chain. The first lever lies with the direct suppliers who produce battery cells. Cell manufacturers contracted by Mercedes Benz are committed to using green electricity in their production facilities to implement energy-efficient processes and continuous emission reduction. Mercedes Benz is also working with specialist partners to convert electrode production processes to green electricity and to integrate innovative technologies.

To actively accelerate the decarbonisation of cell production, Mercedes Benz is applying further specific measures. For example, it is researching dry coating as a forward-looking technology. It replaces energy-intensive drying with hot air and offers considerable potential for carbon reduction, especially in electrode production (cathodes in particular). These cell components are crucial for battery performance, but also for its carbon footprint. Plus, this pioneering technology dispenses entirely with the need for environmentally sensitive additives such as NMP (N-methyl-2-pyrrolidone).

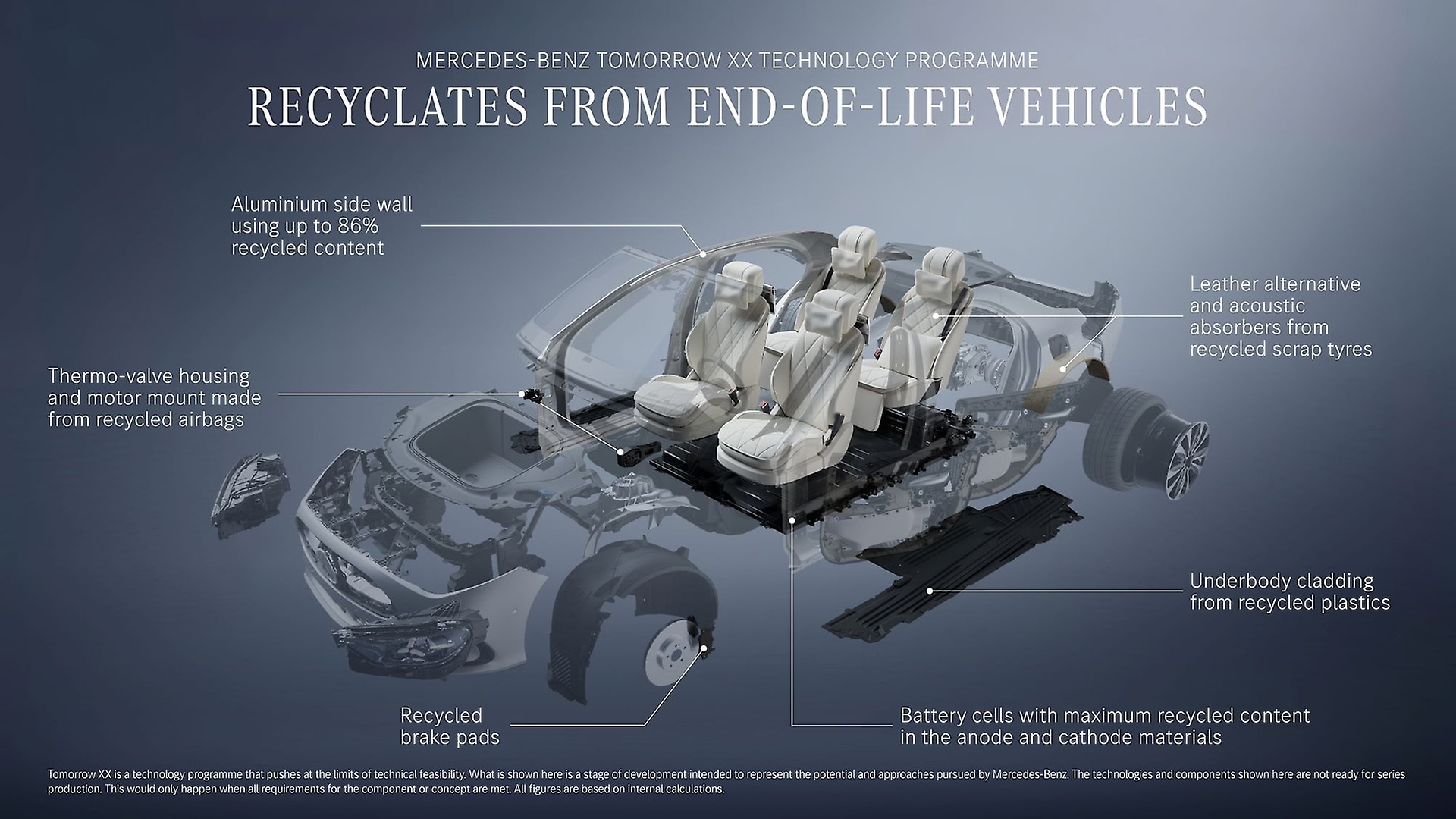

Another lever is the increased use of secondary (recycled) cathode and anode materials in the cells. Mercedes Benz is working with its partners on battery cells made with maximum recycled content in their anode and cathode materials. In addition, the company is testing a pilot battery recycling plant in Kuppenheim, setting new standards for sustainable battery recycling solutions. The aim is to close the entire material loop, thereby making the future of electric mobility even more sustainable.

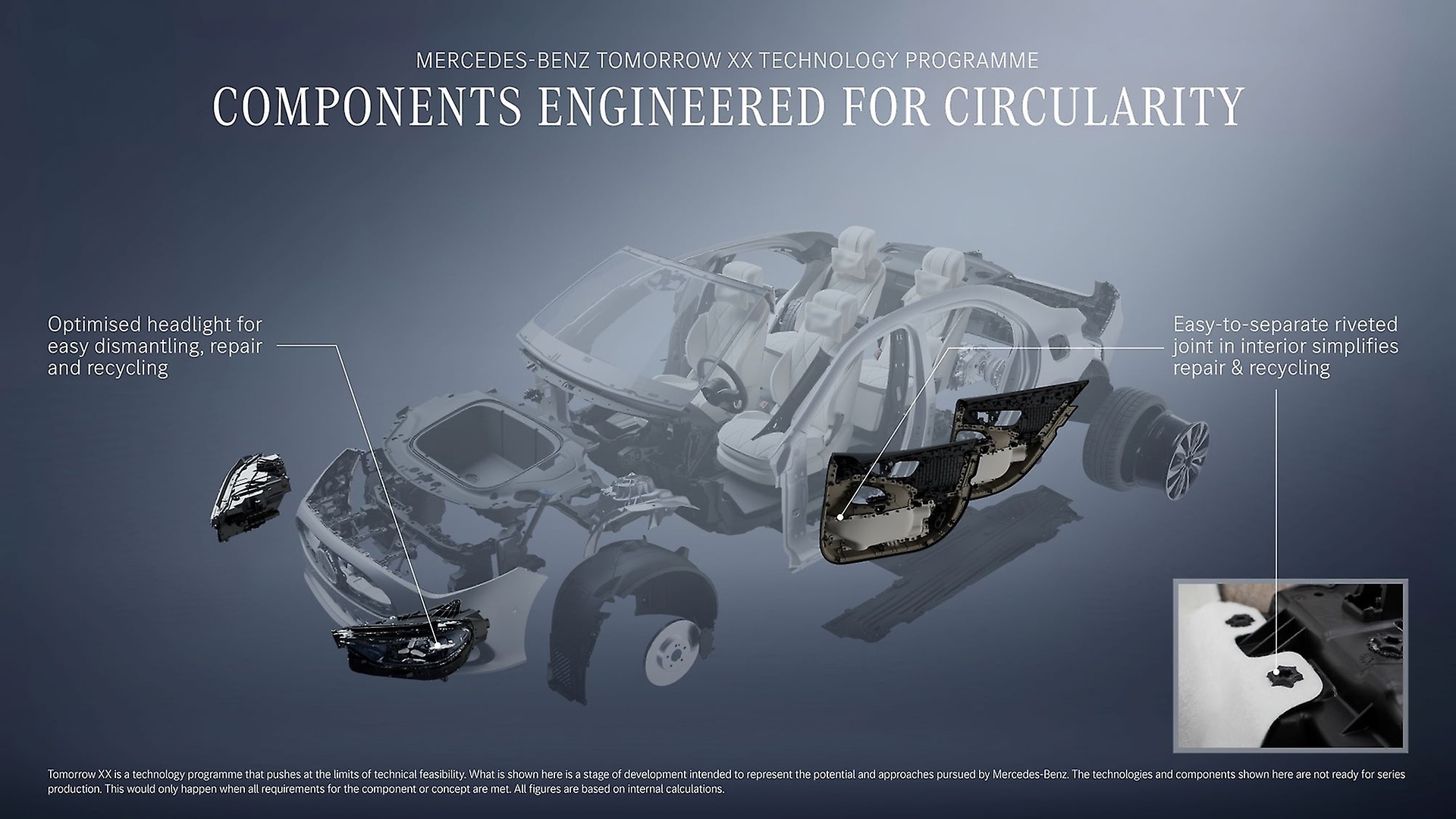

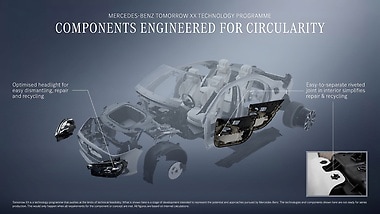

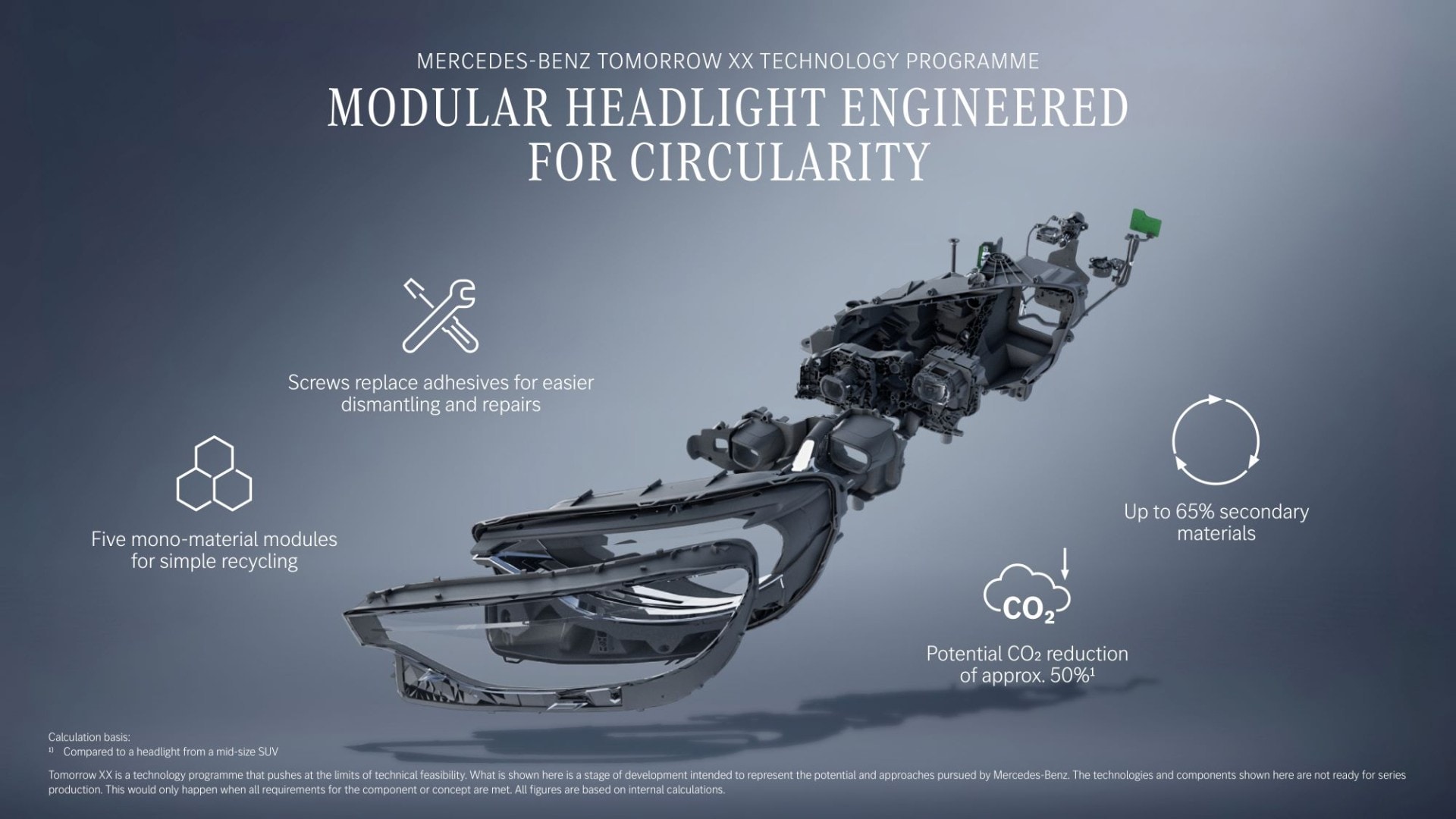

To reduce emissions at battery cell level, Mercedes Benz is also developing concepts that support decarbonisation and recyclate use in the housing and cell module components. The innovative battery system of the new Mercedes Benz MMA platform already incorporates aspects of “Design for Circularity”. Using recyclable materials with existing circular economies – such as steel – can significantly reduce the carbon footprint. To improve recycling efficiency, the components are designed according to the “Design for Circularity” approach. This means not using composite components or permanent (non-separable) joining techniques. Being able to disassemble and sort individual parts of a component can improve the quality of the recovered materials.

,xPosition=0,yPosition=0.5)

,xPosition=1.0,yPosition=0)

,xPosition=1.0,yPosition=0)

,xPosition=0.5,yPosition=0)