March 05, 2021 – Untertürkheim to become a technology competence centre with a campus focusing clearly on electric drive and battery technology, including the production of lithium-ion cells.

,xPosition=0,yPosition=0.5)

Technology competence centre

Mercedes-Benz AG

Mercedesstraße 120

70372 Stuttgart

Germany

Phone: +49 7 11 17-0

E-Mail: dialog@mercedes-benz.com

Please send queries about content on this website to any contact. You can address your concerns to us in English and your respective national language.

Represented by the Board of Management:

Ola Källenius, Chairman; Jörg Burzer, Mathias Geisen, Olaf Schick, Michael Schiebe, Britta Seeger, Oliver Thöne, Harald Wilhelm

Chairman of the Supervisory Board: Martin Brudermüller

Court of Registry: Stuttgart; commercial register no. 762873

VAT ID: DE 32 12 81 763

All information about our products can be found on your country-specific Mercedes-Benz product page.

,xPosition=0,yPosition=0.5)

Technology competence centre

March 05, 2021 – Untertürkheim to become a technology competence centre with a campus focusing clearly on electric drive and battery technology, including the production of lithium-ion cells.

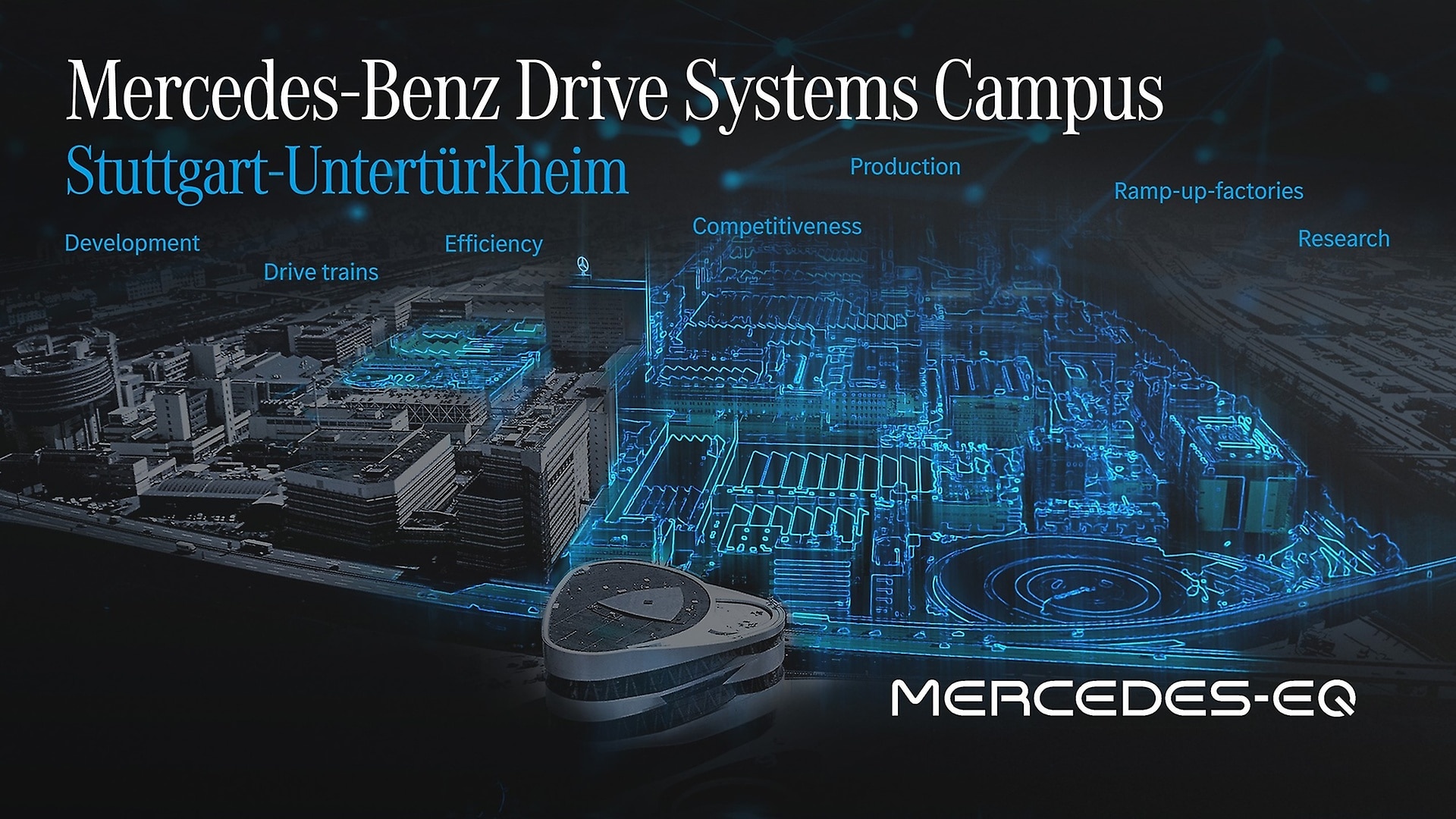

Mercedes-Benz is transforming its Mercedes-Benz Drive Systems unit and its Stuttgart-Untertürkheim site for an “Electric First” future in the context of Ambition 2039 – the company’s path toward carbon neutrality. Mercedes-Benz is thus underpinning its new strategy, which was presented in October 2020. After intensive negotiations, the management and works council of the Mercedes-Benz Untertürkheim plant in Germany reached an agreement to invest a three-digit million euro amount to transform Untertürkheim, the largest site in the company’s global powertrain production network which will in future be known as the “Mercedes-Benz Drive Systems Campus”. The site will focus on research, development and production ramp-ups of drive systems.

The agreement strengthens Untertürkheim’s role as a development and qualification hub for drive technologies and further expands its already broad expertise in the field of e-mobility - through a campus for electric and electrified drive systems. A new factory for the small-series production of future battery cells, and a dedicated battery safety lab, will complement Mercedes-Benz's existing research and development activities in the field of battery technology. The company strives for a holistic approach which ranges from basic research and development to manufacturing of battery systems. In terms of series production, the site will focus increasingly on electric drive components - battery and electric drive systems, while conventional engine, transmission and component production will gradually be phased out, which will effect employment profiles and scopes.

The Mercedes-Benz Drive Systems Campus is a crucial development step regarding the sustainable transformation of the Untertürkheim site. At the same time, this requires substantial adjustments in its production program and processes. In this context, the existing competence centres will be restructured or systematically expanded. The close link of research, development and production at the same location will create important preconditions for synergies and unique know-how strengthening the vertical integration in house as a key pillar.

With the bundling and extension of its battery activities the company further strengthens its expertise in the field of e-mobility. Widespread research and development activities are already anchored at the location, such as the e-technology centre and cell technology centre, where, among other things, prototypes for the electric drive system are built and cell technologies are researched and tested. Additionally, the battery research and development activities currently located at the Nabern part of the plant, including various test benches, are to be located on the campus in the future. Further investments are planned in the significant expansion of the current cell technology centre in order to be able to cover the entire value chain of battery technology. In addition to basic research, pre-development and design of battery cells, a new factory for the small-series production of lithium-ion battery cells is being planned, starting operations in 2023.

The sustainability factor, transparent cell development through to recyclability, plays a major role in this. Moreover a dedicated battery safety lab will complement Mercedes-Benz's activities. In future, the company will cover almost the entire field of battery technology at its Untertürkheim location - right down to battery systems which are manufactured at the site. The battery factory in Brühl nearby will produce batteries for plug-in hybrid vehicles from 2022. Starting this year, battery systems for the Mercedes-Benz model EQS - the all-electric member of the S-Class family - will roll off the assembly line at the Hedelfingen part of the plant. The EQS will be manufactured at Factory 56 in Sindelfingen some 20 km away starting in the first half of 2021. The battery system for the EQE will also be produced in Hedelfingen.

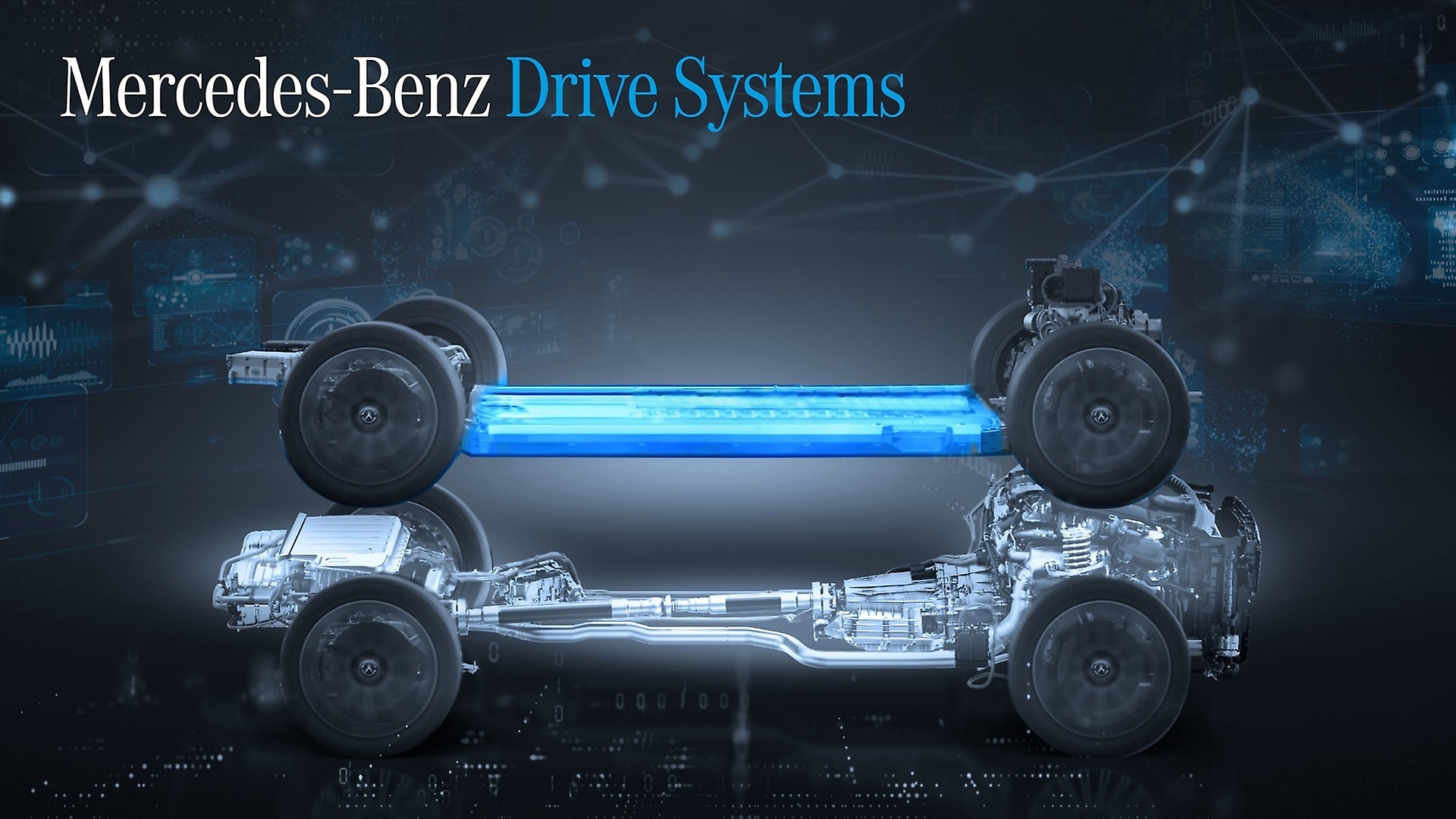

The company moreover is setting a clear focus on the development of the highly efficient electric drive system, the intelligent combination of electric motor, battery system, power electronics and software through to series maturity including testing. The next generation of electric motors are being developed in house and will feature inverter and high voltage technology. The manufacturing and assembly of electric drive systems parts for future vehicle models of Mercedes-Benz brand will start at the end of 2024 and round off the product portfolio with the battery factories in Hedelfingen and Brühl. The previously planned production volumes of electric drive systems will double.

With regard to the series production volumes of conventional powertrains at the Untertürkheim location, Mercedes-Benz will even more benefit from the flexibility of its global powertrain production network in future. New production volumes are being examined in detail in order to maximize efficiency and profitability.

On the employment side, this leads in the medium term to changes in employment profiles, for which the company prepares its employees with targeted qualification measures. The reduction of series production volumes of conventional powertrains will also lead to adjustments of personnel at the Untertürkheim location. The company is preparing for this with various measures and the top priority is to implement structural and personnel measures in a socially acceptable manner with regard to the jobs affected.