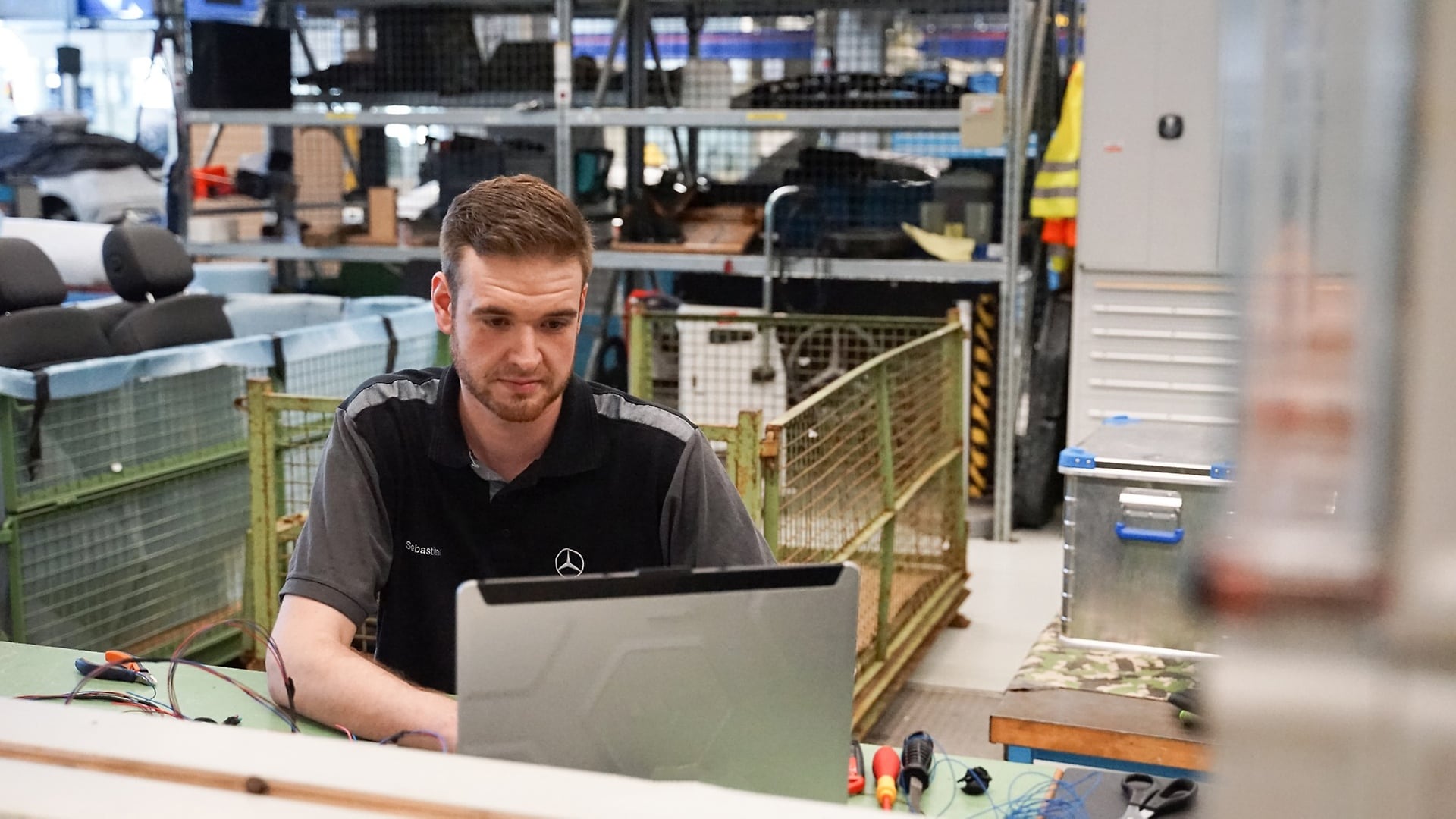

Sebastian, you are one of the first automotive mechatronics technicians to specialise in system and high-voltage technology. What is special about this training?

The training prepares prospective automotive mechatronics technicians for the new requirements when working on modern vehicles. For example, you learn about the latest electric and hybrid drives, battery technologies, new onboard networks and charging systems. With comfort, safety and assistance systems, as well as automated driving systems, cars are constantly evolving. But the training also includes the classic disciplines such as mechanics, which vehicles won't be able to do without in the future either (laughs).

How did you come to do your training?

I have always liked to tinker, tinkering with my scooter in the garage at the weekend and later with my car. I was simply interested in how everything works and is connected. After leaving school, I wanted to do something practical. An acquaintance had told me about a selection process. Of course, that was right up my alley. I applied and was soon invited to the test and interview. And soon after that I had been accepted.

So in 2017 you started your training …

Yes! By the way, I started with a classic automotive mechatronics apprenticeship. In the second year of the apprenticeship, our supervisor then asked us if we could imagine specialising in system and high-voltage technology. I was enthusiastic right away because it was clear to me that this is the future, and I wanted to be a part of it. My colleagues and I were the very first to be trained on electric vehicles. After that I went straight to the factory to work in the rework department, where I became an electrics specialist.

Today you work at the start-up factory in Sindelfingen, among other places. What is this about?

In a nutshell: We equip test vehicles with newly developed systems or build complete prototypes. The vehicles we work on will later be used on the test track and in test bench trials, for example - or are on the roads around Stuttgart as disguised prototypes.

And what does the start-up factory look like?

Actually, it looks like a normal car workshop, only much, much bigger (laughs)! We often work on eight or nine vehicles at the same time. The difference is that we work on technologies and vehicles that are not even on the market yet. We do this in cooperation with our colleagues from Development, and receive instructions from there as to which control units should be installed and how the individual systems are to be connected to each other. Every vehicle is new and different, which makes it really exciting.