Hello Lorena! You started your training in process mechanics and coating technology at Mercedes-Benz in 2018. What do you like about it the most?

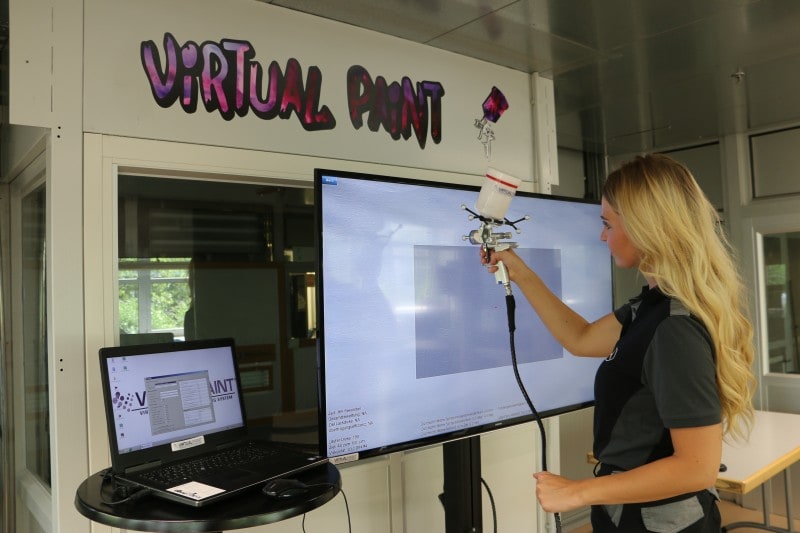

The training is unbelievably varied. We learn techniques for grinding, polishing, painting, designing and applying graphic foils, as well as how to operate and service robots in production. I especially like the painting and polishing part because during it I can always keep moving and can also be creative. That was also one reason why I chose the training.

How did you find out about the vocational training?

After graduating from secondary school, I went through different internships. For example, I did an internship in retail, in a kindergarten, a hotel and at various industrial businesses. I quickly noticed that I want to work with my hands. Another reason was that my father is a vintage car fan and I have been helping him paint car bodies since I was a kid. I also went to the "Vocational training live!" Day ("Ausbildung live!“-Tag) at Mercedes-Benz in Sindelfingen with my two brothers and got some initial impressions of the work here in the workshop. I found that very exciting. That is why I applied.

How were things for you in the beginning?

As with every new beginning, I was excited but also wondered whether I would get along with my coworkers and superiors. Then, when I came into the workshop for the first time, I felt comfortable right away. We were given a very warm welcome by our master craftsmen and vocational trainers and got to know each other in the group. We started the training with ten people and we’re a really great group - almost like a big family. Besides that we have also been given trainee advisors.