Mercedes-Benz not only supports the responsible procurement of raw materials in battery cells, for example cobalt – but also of "classic" raw materials such as aluminium, mica or steel. In addition, we are committed to various general and specific raw material initiatives designed to improve sustainability in supply chains.

With each of the initiatives, the company is pursuing specific objectives. As platforms, they enable us to work together with relevant stakeholders, and also provide control mechanisms such as certification systems and standards that promote the sustainable sourcing of raw materials. By cooperating with other actors such as NGOs or businesses, we are able to combine our strengths in these initiatives.

With the Initiative for Responsible Mining Assurance (IRMA)

Mercedes-Benz Group AG joined IRMA to promote the broad application of robust and comparable sustainability standards – also as a precondition for supplier decisions and contracts. Where robust certificates exist, we monitor this with the block chain technology we have already been testing in pilot projects since 2018.

In order to prevent materials associated with conflicts from entering the supply chain, Mercedes-Benz Group AG has joined the Responsible Minerals Initiative

Mica is used to produce the shimmering effect in vehicle paints. In joining the Responsible Mica Initiative

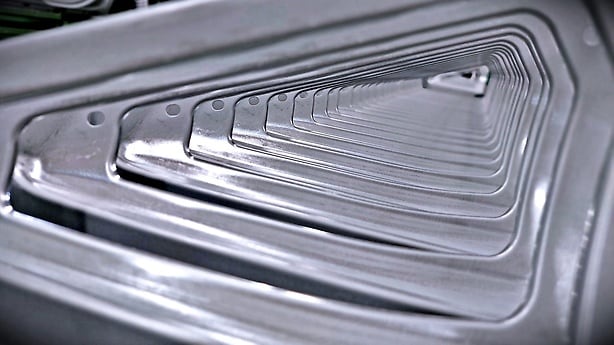

Aluminium is becoming increasingly important as a material in electric vehicles, as it is much lighter than steel. Mercedes-Benz is part of the non-profit Aluminium Stewardship Initiative

Steel is the most widely used material in cars and is the world's largest raw materials industry. Steel production is linked to many ethical, ecological and social aspects along the entire value chain, and to date these are not taken into account in any standardised guidelines for the companies.

The non-profit Responsible Steel Initiative (RSI)

Mercedes-Benz Group AG is lead partner of the industry initiative Drive Sustainability

This page was last updated on 07.12.2023.