Our vehicles are driven electrically – with a battery, as a hybrid or with a fuel cell. The drive technology has changed and it will continue to change.

Our drive. The technology of the vehicles

The drive system of a battery-operated electric car consists of the electric motor, a high-voltage battery, power electronics and a charger. The vehicle is propelled by the electric motor, which obtains its power from the high-voltage battery. This battery is charged both externally from the power network and by recuperation during the journey.

Electric vehicle drives need battery systems which satisfy the specific requirements with respect to safety and the environment, performance, durability, service life and costs.

The Mercedes-Benz subsidiary company ACCUMOTIVE develops and produces lithium-ion batteries for hybrid and electric vehicles for the Mercedes-Benz and smart brands.

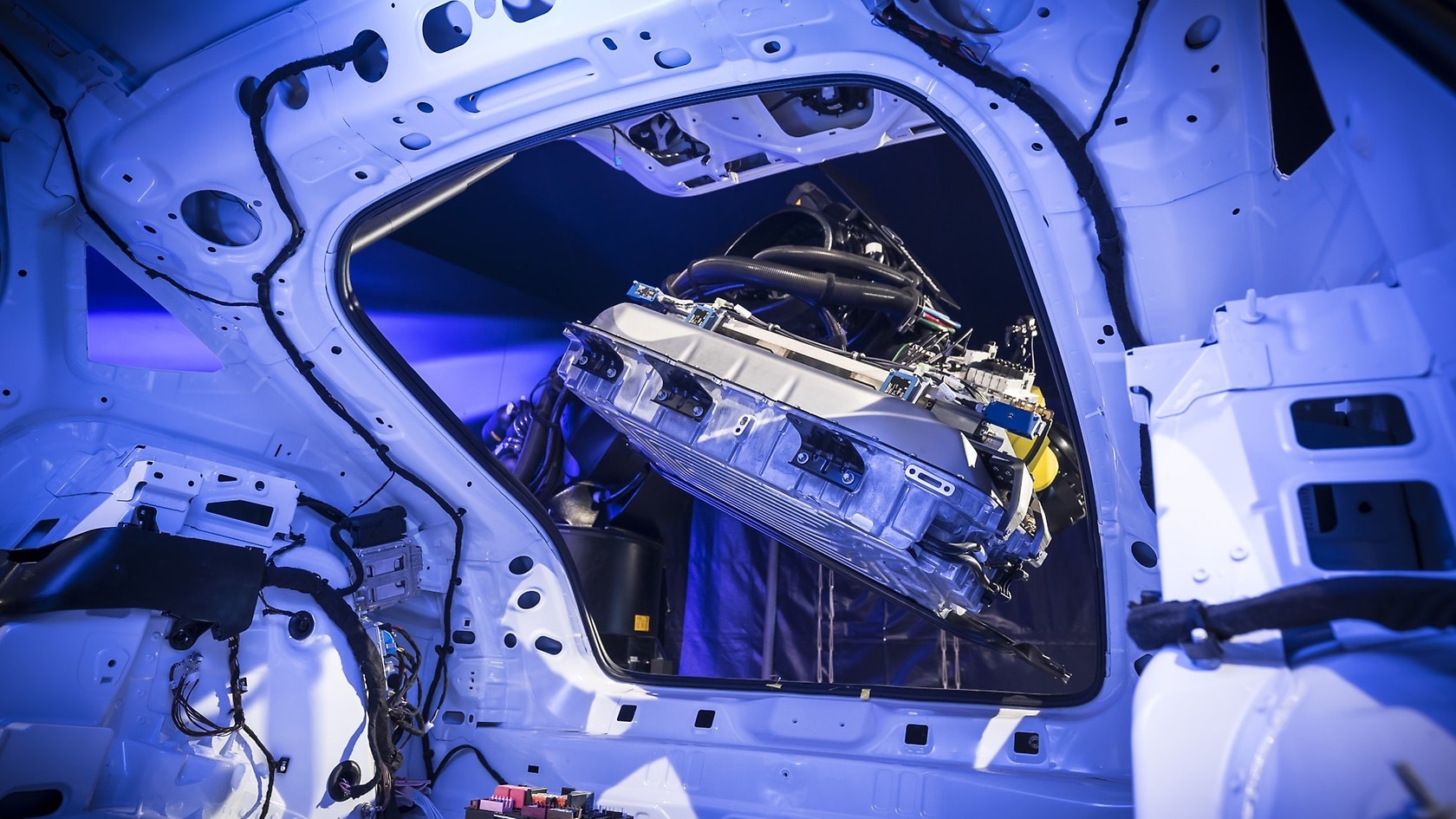

Innovator: Structure of a lithium-ion battery

A battery consists of various components: Battery block with rechargeable cells, battery management system, control electronics, cooling and housing.

The core of every battery is the lithium-ion cells, which may be combined into modules again, depending on the structure and size of the battery. In order to produce a battery from the individual cells, the cells have to be connected. This is carried out mechanically on the one hand and by means of electrical interconnections on the other. For the monitoring of the battery status and the individual cells, as well as for power regulation, each battery has a battery management system (BMS) with an individual software. The installation-space-optimized housing of the battery is used to protect the components against contamination and mechanical stress.

Driving with hybrid

Across all vehicle ranges, Daimler has the most extensive and best-selling hybrid offering in the premium segment. The focus is currently on plug-in hybrids in the passenger car segment, too: By 2017, the Group will have a total of ten such models on the market. Because today the concept of the plug-in hybrid offers the perfect compromise between electric and conventional mobility.

The centerpiece of the hybrid vehicle is the hybrid transmission with hybrid traction head. In addition to the conventional transmission, the hybrid traction head also integrates the torque converter with bridging clutch, the electric machine and a disconnecting clutch for decoupling the internal combustion engine for the exclusive electric mode. It has a modular structure and can be used in any Mercedes-Benz model series with a longitudinally installed powertrain due to its compact design.

How do the electric machine and internal combustion engine work together?

- If the hybrid vehicle is running exclusively in electric mode, the coupling is open, the combustion engine is decoupled and switched off.

- During recuperation, the coupling remains open, with the electric machine then working as a alternator and converting mechanical energy into electrical energy to charge the battery.

- When the vehicle is running in hybrid mode, the coupling is closed. In terms of the comfort and efficiency criteria, the intelligent hybrid control system operates the internal combustion engine and electric machine.

- In coasting mode the coupling is open and the combustion engine is switched off. The vehicle coasts without the drag losses of the combustion engine.

- Boost: Beyond the full load of the combustion engine, power is also supplied by the electric machine.

The technology of the plug-in hybrid vehicles combines the advantages of the combustion engine with those of the electric drive. This helps to reduce the overall consumption and improve performance, as the electric drive replaces or supports the combustion engine where the latter displays rather unfavorable behavior. Furthermore, plug-in hybrid vehicles have such a large battery that in urban traffic they can be driven exclusively in electric mode and therefore locally free of emissions without any problems; however, the combustion engine is then used for greater distances, ensuring that the vehicle is suitable for long-distance driving.

Electric vehicles with fuel-cell drive are also suitable for long driving distances thanks to their greater range and faster refueling. The electricity is generated in the vehicle itself from hydrogen, which is filled into the tank as in a conventional vehicle. Emission-free driving will only become attractive to customers for longer distances if sufficient fueling stations become available. That is why Mercedes-Benz is promoting the development of a comprehensive hydrogen infrastructure jointly with partners from politics and the energy sector. That fuel-cell vehicles can be built in series production was demonstrated in 2014 by a B-Class F-CELL from the current fuel-cell fleet of Mercedes-Benz. The vehicle set an endurance record of 300,000 kilometers driven under normal everyday conditions.

H2 mobility: Partnership for hydrogen

By founding the joint venture H2 MOBILITY Deutschland GmbH & Co.KG, Mercedes-Benzand its partners Air Liquide, Linde, OMV, Shell and Total have laid the foundation for the gradual expansion of the nationwide hydrogen (H2) refueling network. The H2 MOBILITY initiative plans a network of around 400 H2 filling stations in Germany by 2023. This would make Germany the first country to have a nationwide network for refueling fuel cell powered vehicles with hydrogen. Investments totaling around EUR 400 million are planned.